Solein's secret? A Finnish microbe that turns air into 80% protein. Not extracted, not isolated -- you're eating the whole dried cell with natural B12, iron, fiber, and whey-level amino acids. Ancient biological tech meets modern scale.

In our previous deep dive into Solein®'s production technology, we explored the impressive industrial hardware that makes protein from air possible: the gas fermentation bioreactors, the water electrolysis systems, and the precision engineering of Factory 01. But that article only told half the story.

While the industrial technology does deserve attention, there's another form of technology at work... but it's one that doesn't involve wires, metal, or computer chips. It's biological technology, refined over millions of years of evolution in the pristine environment of Finland. It's the microbe itself.

Solein® from Solar Foods: Powered by a Different Type of Technology

When most people hear the word "technology", they think of the latest smartphone, AI tools, or advanced manufacturing equipment. But technology is simply a sophisticated system that solves problems efficiently. And by that definition, the hydrogen-oxidizing microbe that produces Solein® might be the most elegant piece of technology in the entire protein production process.

This microbe doesn't just assist in making Solein® -- it is Solein®. After pasteurization and drying, the entire cellular biomass becomes the golden protein powder that's revolutionizing the supplement industry. This isn't precision fermentation where genetically-modified microbes or yeast produce proteins that get extracted and separated. This is biomass fermentation, where the microbe itself becomes the complete, nutritious final product.

As we discussed with Solar Foods' team in our podcast episode #175, understanding this distinction is critical to appreciating what makes Solein® so revolutionary. You're not eating something the microbe made -- you're eating the production system itself, with all its complete amino acids, naturally occurring B12, exceptional iron content, and functional beta-glucans intact.

Ready to meet the microscopic organism that's redefining protein nutrition? Let's explore the living technology that transforms air into one of the most complete protein sources available. Before we dive in, subscribe to PricePlow's Solar Foods and Solein® alerts:

Subscribe to PricePlow's Newsletter and Alerts on These Topics

The Microbe: Nature’s Protein Factory Built Over Millions of Years

Ancient Nordic Origins: A Discovery in Finnish Biodiversity

The story of Solein® begins not in a laboratory, but in the rich biodiversity of Finland's natural environment. Solar Foods didn't genetically engineer a new organism or modify existing bacteria to suit their needs. Instead, they discovered something nature had already perfected over millions of years.

As Susanna Mäkinen, Head of Biology at Solar Foods, explains: "The microbe at the heart of Solein®'s story was plucked from the rich biodiversity of Finland's nature. Little did it know that it would be the ancestor of trillions of similar yellow cells."

This microbe belongs to the Xanthobacter genus, a group of hydrogen-oxidizing bacteria (HOB) that evolved the remarkable ability to derive energy from hydrogen gas rather than organic compounds.[1] These organisms are non-GMO -- they're exactly as nature designed them, requiring no genetic modification to perform their protein-producing function.

The discovery of this specific strain is thanks to years of bioprospecting in Finnish ecosystems, searching for organisms with optimal protein synthesis capabilities. What Solar Foods found was a microbe that could efficiently convert gaseous inputs into dense, nutritious biomass at rates that make commercial production viable.

How the Microbe Works: Chemosynthesis as Living Technology

While most life on Earth depends on photosynthesis (the conversion of sunlight into chemical energy by plants), Solein®'s microbes use an entirely different biological process called chemosynthesis.[2]

Instead of capturing photons from the sun, these hydrogen-oxidizing bacteria break the chemical bonds in hydrogen gas molecules, releasing energy in the process. They then use this energy to fix carbon dioxide from the air into organic compounds: proteins, fats, carbohydrates, vitamins, and minerals.

Think of the microbe as a microscopic protein production facility where DNA serves as the blueprint, cellular machinery functions as the assembly line, and air molecules provide both the raw materials and the energy source. The entire operation happens inside a single cell measuring less than 0.5 micrometers in diameter. Tiny, but it can scale to incredible levels.

This chemosynthetic process is remarkably efficient. As covered in our technology article, the overall system can be 20 times more efficient than photosynthesis when accounting for all inputs. But that efficiency isn't just about the industrial process, it's about how good the microbe itself is at its job.

As Laura Sinisalo from Solar Foods emphasized to us, "The microbe does the heavy lifting in this process." The industrial equipment simply creates optimal conditions; the biological conversion from air to protein happens entirely within these ancient single-celled organisms.

The Cell Structure: Understanding What You’re Actually Ingesting

Here's where Solein® fundamentally differs from many alternative proteins, and why understanding the biology matters: Solein® is dried microbes. Not protein extracted from microbes. Not compounds produced by microbes. Not plant material. The whole cellular biomass becomes the ingredient.

Finnish company Solar Foods just made protein powder from literal air! Solein® uses microbes that eat hydrogen + CO2 to produce 78% protein with all essential amino acids. It's also already GRAS self-affirmed and in production.

This is a critical distinction that Laura was careful to clarify: "Solein is not a byproduct of the microbe. We use the whole biomass, so Solein is actually 'dried microbes.'"

Every component of the microbial cell contributes nutritional value to the final powder:

- The cell envelope and cell wall contain beta-glucans, which are functional dietary fibers with immune-supporting properties. These structural components make up 40% of Solein®'s total fiber content (which makes up 10% of the product). Most protein powders have zero fiber, but Solein®'s fiber comes naturally from eating the complete microbe.

- The protein synthesis machinery (the ribosomes, transfer RNAs, and all the cellular equipment for assembling amino acids) contains the very proteins that make Solein® such a complete amino acid source. The microbe isn't producing protein for you to extract, the microbe's own structural and functional proteins are the product.

- Natural pigmentation compounds including carotenoids provide the distinctive golden-yellow color while delivering antioxidant benefits. These aren't added during processing, they're compounds the microbe produces for its own survival that happen to be beneficial for human health.

- The genetic material and associated vitamins naturally present in the cell contribute nutrients like vitamin B12, which is synthesized by the microbe as part of its normal metabolism. At 5 micrograms per 100g, this naturally occurring B12 addresses one of the biggest nutritional gaps in plant-based proteins.

- The cell membrane, composed primarily of unsaturated fatty acids including oleic acid (Omega-9), provides the 6% fat content in Solein®. These are heart-healthy lipids that contribute to the creamier mouthfeel described in our podcast discussion.

The remarkable efficiency becomes clear: The microbe is essentially a protein-packed cellular package where nearly every component offers nutritional value. At approximately 78-80% protein by dry weight, these cells are among the most protein-dense biological structures in nature.

Why “Biomass Fermentation” Changes Everything

If you've been following alternative protein developments, you've probably heard about the companies excelling in "precision fermentation". Solar Foods' approach is fundamentally different, and understanding this distinction is essential.

As explained in our conversation and initial project call: "In biomass fermentation, we have the microbe and we basically feed the microbe through the fermentation process and then we basically pasteurize this microbe. We dry it and everything becomes our ingredient."

Precision fermentation works like this:

- Start with genetically modified microorganisms (often yeast modified with CRISPR)

- Feed them substrates (usually sugar from crops)

- The modified microbes produce specific target proteins (like beta-lactoglobulin or lactoferrin)

- Separate the target proteins from the microbial biomass through extensive downstream processing

- Discard the microbial biomass as waste

- End up with isolated proteins that need to be formulated with other ingredients

Biomass fermentation (Solar Foods' approach):

- Start with non-GMO naturally occurring microbes

- Feed them gases from air (hydrogen, carbon dioxide, oxygen) plus minerals

- The microbes grow and multiply, building complete cellular nutrition

- Pasteurize to ensure food safety

- Dry the complete biomass into powder

- The entire microbe becomes the ingredient -- nothing (besides water) is separated or discarded

- Zero microbial waste, complete nutritional profile intact

This parallels humanity's oldest fermentation traditions: "What you have in beer, what you have in cheese, yogurt production that's the same natural fermentation where you basically have the microbe becoming part of the product at the end. You're not separating it."

The efficiency advantage is substantial. Precision fermentation requires complex separation equipment, produces significant waste biomass, and often needs additional fortification since you're working with isolated proteins. Biomass fermentation is inherently more efficient: everything produced has value, the nutritional profile is naturally complete, and processing is simpler.

This also explains why Solein® has such a complete nutritional profile compared to isolated protein ingredients. The iron, the B12, the fiber, the healthy fats, and more come naturally from the whole cellular biomass, not from fortification after the fact, because they're essential to the organism's life.

The Reproduction Cycle: From One Cell to Endless Protein

One of the most elegant aspects of Solar Foods' technology is the reproductive capability of the microbe itself. As Laura explained: "We start from one microbe we have found already some years ago and this one microbe divides endlessly. So the big idea is that we never run out of food from this one seed we have once discovered."

Solar Foods' Factory 01 in Finland produces Solein® protein from air molecules using chemosynthesis microbes. 20x more efficient than photosynthesis, no farms needed. Commercial protein production from literal air is now reality.

Inside Factory 01's bioreactors, the fermentation cycle runs for approximately 3 days. During this time, the microbes consume their carefully balanced gas diet: hydrogen for energy, carbon dioxide for carbon, oxygen for cellular respiration, and essential minerals including nitrogen, phosphorus, sulfur, and iron.

As they consume these inputs, the microbes do what all living organisms do: they grow and reproduce. Each cell divides, creating two identical daughter cells. Those cells divide again. And again. Over 72 hours, trillions upon trillions of cells are born, each one building its cellular structures from air molecules, each one packing itself with protein, fiber, vitamins, and minerals.

"From this one seed we are constantly producing food," Laura notes, "because when we put it in the medium and feed the gas into the tank, it starts doing what nature does on a cellular level: dividing endlessly."

After the fermentation cycle completes, pasteurization ensures food safety by inactivating the microbes. Drying then removes water, concentrating the biomass into a flour-like powder. The result: approximately 80% protein by dry weight, ready for incorporation into food and supplement products.

This continuous reproductive cycle is what makes Factory 01's "every day is a harvest day" model possible, as we discussed in our Solein® technology article. Unlike crops that need months to grow or animals that require years to mature, these microbes produce harvestable protein biomass every 72 hours, year-round, regardless of weather or seasons.

Nutritional Profile: The Microbe’s Gift to Human Nutrition

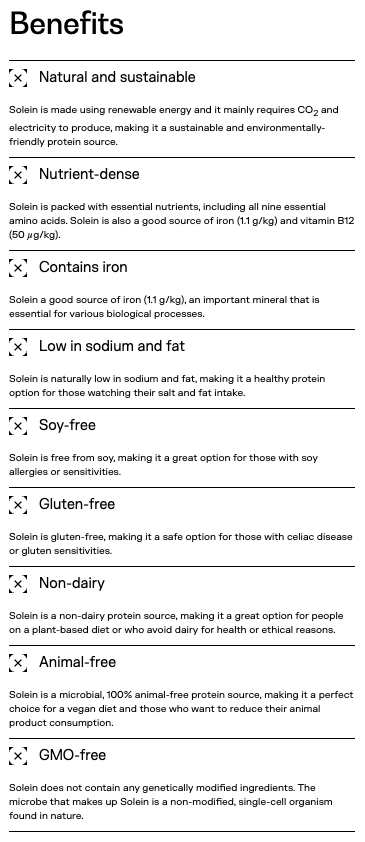

Now that we understand what Solein® actually is, let's examine what that means nutritionally. The numbers are impressive, but they're even more remarkable when understanding that they come naturally from the microbe's own cellular composition.

Solein®’s Complete Macronutrient Breakdown by Percentage:

- 80% Protein with complete amino acid profile

- ~10% Dietary Fiber (40% of which are beta-glucans from cell walls)

- ~6% Unsaturated Fats (primarily oleic acid/Omega-9)

- ~4% Minerals & Vitamins (including naturally occurring iron and B12)

The microbe has essentially optimized itself to be a protein production machine, with 80% of its dry weight is protein. That's higher than most isolated protein ingredients and far higher than whole food protein sources.

The 10% fiber content is unusual for a protein supplement, but makes sense given that it comes from the structural components of the cell (primarily the cell wall beta-glucans). With Solein®, you get the complete nutritional package.

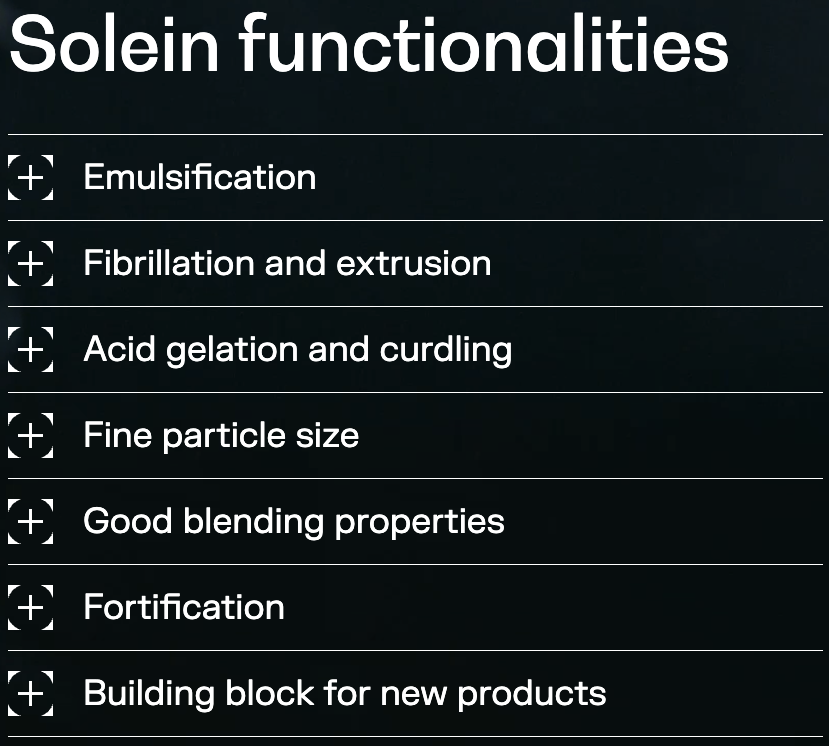

The 6% fat content, composed primarily of unsaturated fatty acids, contributes to Solein®'s creamy mouthfeel without adding inflammatory fats or cholesterol. As Sini noted in Episode #175 of our podcast, this fat profile enables excellent emulsification properties in beverage applications.

Amino Acid Profile: Where Solein® Rivals Whey

The amino acid composition is where Solein® truly shines and where the benefits of whole-biomass fermentation become most apparent.

Solein® contains 43% essential amino acids, matching whey protein exactly. This means that of the 80% total protein content, 43% consists of the essential nine amino acids humans cannot synthesize and must obtain from diet: histidine, isoleucine, leucine, lysine, methionine, phenylalanine, threonine, tryptophan, and valine.

The branched-chain amino acid (BCAA) content hits 20%, with leucine as the dominant BCAA at 9% of total protein. For context:

- Whey protein: 24% BCAAs

- Solein®: 20% BCAAs

- Soy protein: 18% BCAAs

- Pea protein: 17% BCAAs

- Fava bean protein: 16% BCAAs

- Rice protein: 15% BCAAs

Solein® slots in just below whey and well above plant-based alternatives. That 9% leucine content is especially important, since leucine is the primary trigger for muscle protein synthesis, making it critical for athletic recovery and muscle maintenance applications.

Solein® also achieves a theoretical Protein Digestibility-Corrected Amino Acid Score (PDCAAS) of 1.0, the highest possible rating, indicating that the body can effectively utilize nearly all the amino acids provided. This puts Solein® in the same elite category as whey protein and whole eggs.

Compare this to plant proteins:

- Soy: 0.9-1.0

- Pea: 0.82-0.93

- Fava bean: 0.7-0.8

- Rice: 0.47-0.60

Solein® delivers animal-protein-level amino acid completeness and digestibility without any animal products, antibiotics, hormones, or the environmental costs of animal agriculture.

Beta-Glucans: The Fiber Advantage

The 4% beta-glucan content (representing 40% of total dietary fiber) deserves special attention. Beta-glucans are functional fibers with documented benefits for immune function, cholesterol management, and gut health.[3]

These beta-glucans come from the cell walls of the microbe, effectively the structural scaffolding that gives the cell its shape and integrity. When you eat Solein®, you're ingesting these cell walls along with everything else, providing functional fiber that whey protein completely lacks (0% fiber) and that most plant proteins provide only in modest amounts without the specific beta-glucan structure.

This is one of the clearest examples of how whole-biomass fermentation creates nutritional advantages. The cell walls aren't waste to be discarded; they're valuable nutrition to be consumed.

Micronutrient Powerhouse: What the Microbe Naturally Produces

Here's where Solein®'s whole-microbe approach really differentiates it from isolated proteins:

-

Vitamin B12: 5 micrograms per 100g

This is naturally-produced by the microbe as part of its normal metabolic processes. Vitamin B12 is critical for nerve function, DNA synthesis, and red blood cell formation, yet it's absent from plant proteins and low in whey protein (<0.5 micrograms per 100g).

For anyone following plant-based diets or reducing animal product consumption, finding naturally occurring B12 is challenging. Solein® solves this problem not through fortification, but because the microbe naturally synthesizes B12 and that vitamin remains in the dried cellular biomass.

-

Iron: 110mg per 100g

This exceptional iron content comes from the microbe's own metabolic needs. Iron is essential for many cellular processes, so the microbe concentrates it within its cells. Compare this to:

- Whey protein: 0.3mg

- Pea protein: 2-3mg

- Rice protein: 1mg

- Soy protein: 1-2mg

- Fava bean protein: 2-3mg

Iron deficiency affects women disproportionately, making Solein®'s naturally high iron content especially valuable for female athletes and active individuals.

-

Calcium: 110mg per 100g

While not as high as whey protein (160mg), Solein®'s calcium content matches soy protein and significantly exceeds most other plant proteins (30mg for pea, 10mg for rice, 60mg for fava bean). This naturally occurring calcium supports bone health, muscle contraction, and various metabolic functions.

-

Natural Antioxidants: Carotenoids Including Beta-Carotene

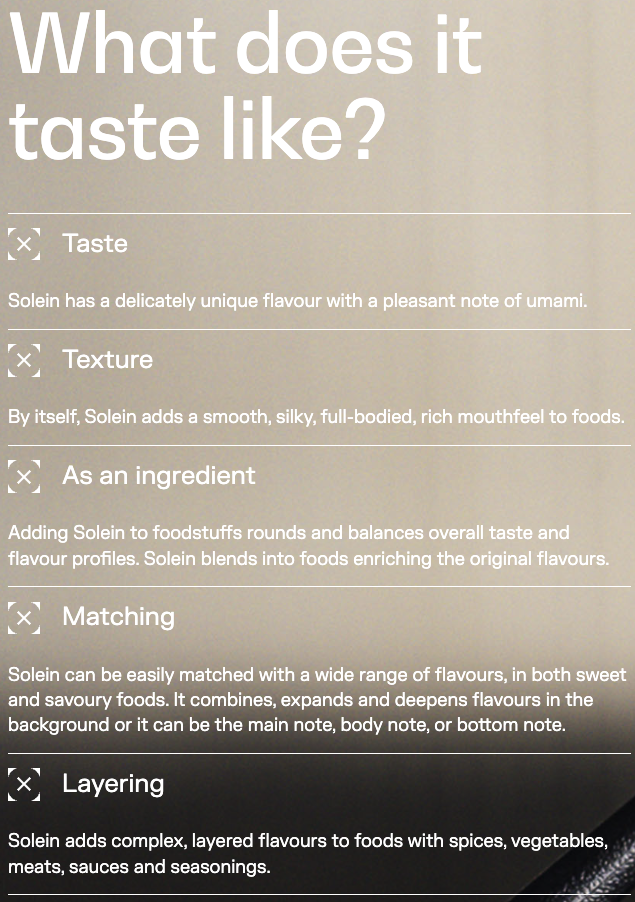

The golden-yellow color of Solein® comes from carotenoids that the microbe produces for its own cellular functions. These pigments act as antioxidants, helping protect cellular structures from oxidative stress. When you eat Solein®, you're getting these protective compounds as a bonus nutritional benefit.

This is biological elegance in action: the microbe produces these compounds for its survival, and those same compounds provide antioxidant benefits for human health, and research has shown that beta-carotene is best derived from diets, not synthetic supplements.

-

Unsaturated Fats: The Healthy Lipid Profile

The 6% fat content consists primarily of oleic acid, the same heart-healthy Omega-9 fatty acid that makes olive oil nutritionally prized. This fat comes from the microbe's cell membrane (the lipid bilayer that surrounds the cell and regulates what enters and exits).

Unlike whey protein, Solein® contains no saturated fats or cholesterol, and unlike many plant proteins that are largely defatted during processing, Solein® retains the natural fat profile of the whole microbe, contributing to its creamy mouthfeel and excellent functionality in formulations.

A natural emulsifier: Fewer additives needed

Solar Foods brings Solein® air-based protein to SupplySide Global 2025. Sample RTD beverages, protein shakes, and bars at Sensapure Flavors Booth 2651. Experience protein made 20x more efficiently than photosynthesis.

These membrane lipids also contribute to Solein®'s emulsification properties. When oils are incorporated into Solein®-based formulas, the protein naturally emulsifies these fats, creating smooth, creamy products without requiring additional emulsifiers or stabilizers.

Solein® vs. Traditional Proteins: The Best of Both Worlds

Ultimately, you're left with the best of all world:

- Protein content that matches and exceeds most whey protein ingredients

- Amino acid content that is bested only by whey protein

- Iron content unlike any other ingredient

- Calcium content on par with soy

- Natural fiber content that isn't removed

- Vitamin B12 content that plant-based proteins come nowhere near achieving

- No allergens

- A favorable fatty acid profile with no cholesterol

- Sustainably produced in an animal-free environment with minimal resources

The “No Compromise” Protein

The comparison reveals Solein®'s unique position: it's not trying to be "almost as good as whey" or "a better plant protein". It's offering something genuinely new, with animal-protein-level completeness yet sustainability that goes beyond plant protein, plus unique nutritional advantages (B12, iron, beta-glucans) that neither category provides.

- You get whey-level amino acid completeness without lactose, animal products, or cholesterol.

- You get plant-level sustainability and lower water usage in production without incomplete amino acids, anti-nutritional factors, or digestive issues.

- You get exceptional micronutrients naturally, not through fortification or supplementation.

This is why Solar Foods describes Solein® as setting a new standard in nutritional protein. It's not competing within existing categories; it's creating a new category where nutrition, functionality, and sustainability all converge without compromise.

Why This Matters for the Supplement Industry

For formulators and brands, this whole-biomass approach creates significant advantages:

- Complete nutrition in a single ingredient: Rather than starting with isolated protein and adding fiber, vitamins, and minerals separately, Solein® delivers the complete package. This simplifies formulation, reduces ingredient counts, and creates inherent nutrient synergy.

- No fortification required: The B12, iron, fiber, and healthy fats are naturally present, not added. This supports clean label claims and addresses consumer preferences for "food-based" rather than "added" nutrients.

- Natural nutrient synergy: When nutrients occur together in biological sources rather than being mixed from isolated ingredients, they often exhibit better bioavailability and effectiveness. Solein® provides this naturally occurring nutrient matrix.

- Supply chain simplification: One ingredient provides protein, fiber, B vitamins, iron, and calcium rather than sourcing these components separately. This reduces complexity, potential contamination points, and supply chain vulnerability.

As we discussed in our main Solein® article, this positions the ingredient well for health and performance nutrition applications where consumers value both efficacy and transparency.

Applications and What’s Next

Solein® is already moving beyond ingredient development into real-world applications. Solar Foods will be showcasing concepts at SupplySide Global focused on the health and performance nutrition segment.

"We will be showcasing our new concepts at the Sensapure Flavors Booth," Laura explained. "We're focused on health and performance segments. Those will be products from the category demonstrating how the ingredient works in different kinds of applications."

Sensapure Flavors Booth 2651 at SupplySide Global 2025

Products already in market include ice cream and cookies in Japan (through Aamoto Corporation) and various applications in Singapore, showing that Solein® works across multiple food categories. For the US market, Solar Foods is focusing initially on applications where the nutritional profile really shines: ready-to-mix protein powders, ready-to-drink beverages, and protein bars.

We'll be covering these proof-of-concept applications and the SupplySide Global developments in future PricePlow coverage, so stay subscribed to our Solar Foods and Solein® news alerts.

What's clear is that the microbe and its complete nutritional profile translates into functional, consumer-friendly products. The biology works. The nutrition delivers. The functionality meets market requirements. And Factory 01 is actively producing commercial quantities right now.

The Future of Biological Protein Technology

The distinctive golden color comes from Solar Foods' Xanthobacter microbes -- the same non-GMO organisms that convert hydrogen and CO2 into nutritious protein. Lab technicians regularly sample the protein powder to ensure consistent quality and that characteristic creamy texture with subtle umami notes.

The Xanthobacter strain producing Solein® represents just one discovery from Finland's microbial biodiversity. There are thousands of unique microbial species out there, each with their own biological and functional properties. Solar Foods' bioprospecting efforts continue, exploring other hydrogen-oxidizing bacteria and potentially other microbial groups with unique nutritional profiles. Some microbes might produce higher quantities of specific amino acids. Others might synthesize different bioactive compounds. Some could offer unique functional properties for specific applications.

Each new microbial strain represents millions of years of evolutionary optimization for different metabolic niches. Humanity is just beginning to tap into this vast library of biological solutions that nature has already developed.

The “Discovery of the Next Potato”

Pasi Vainikka, co-founder of Solar Foods, draws a powerful historical parallel: "I'd compare Solein to the discovery of the potato: we are introducing an entirely new crop for humanity to harvest. It's a watershed moment for how we think about food."

When potatoes arrived in Europe from the Americas in the 16th century, they fundamentally transformed food systems and enabled population growth. They didn't replace existing foods, they added to dietary diversity and filled nutritional gaps that previous crops couldn't address.

Solein® follows a similar trajectory. It's not aiming to replace all proteins, just as potatoes didn't replace all grains. Instead, it adds a genuinely new option to humanity's food portfolio: one that can be produced almost anywhere with renewable electricity, that doesn't compete for agricultural land, and that delivers complete nutrition from resources (air and electricity) that were previously useless for food production.

The "previously undiscovered harvest" mentioned in Solar Foods' materials refers to this: humanity has been farming land and animals for millennia, but we've never before been able to harvest protein directly from air. Solein® opens up an entirely new dimension of food production that doesn't displace existing agriculture but rather supplements it with a resource-independent alternative.

Conclusion: The Redefinition of “Protein Technology”

Distinguishing the microbe as "technology" rather than traditional mechanical/digital systems highlights an important conceptual shift in how we think about food innovation.

When most people imagine future food technology, they picture high-tech equipment, artificial intelligence, automation, and advanced manufacturing. And certainly, Solar Foods employs all of these -- Factory 01 is an impressive feat of bioprocess engineering covered in our technology article.

But the most sophisticated technology in the entire system is biological: a microbe that took millions of years to evolve, that can convert air molecules into complete nutrition, that reproduces itself endlessly from a single cell, that packs approximately 80% of its mass into protein, and that does all of this using nothing but chemical energy from hydrogen gas.

This reframes what "advanced food technology" means. Sometimes the most advanced solution isn't the newest invention but rather a biological system that nature already perfected, now scaled through human engineering. The future of food technology may be less about creating entirely new systems and more about discovering and harnessing the biological solutions that already exist in nature's vast microbial library.

With Solein®, you're not eating an isolated, purified protein that's been stripped of its biological context. You're eating complete cellular biomass with all its natural nutrient synergies intact. The fiber from cell walls, the B12 from metabolism, the iron from cellular stores, the beta-glucans from structure... all of it comes naturally from consuming the whole microbe.

This is biomass fermentation at its finest, echoing humanity's oldest fermentation traditions (bread, cheese, yogurt, beer) where microbes become part of the food, not just tools to produce food. But unlike those ancient fermentations that rely on agricultural inputs, Solein®'s microbes operate on an entirely different resource base: literal air.

Juan Benítez-García and Sini Möttönen from Solar Foods reveal how ancient Finnish microbes and renewable electricity create Solein®, the revolutionary protein made "out of thin air" on Episode #175 of the PricePlow Podcast.

A New Protein Paradigm

Together, the industrial technology and the biological technology represent a complete rethinking of how protein gets made. The hardware creates optimal conditions. The microbe does the actual work. And the result is a new category of protein that compromises on neither nutrition nor sustainability.

As Pasi Vainikka suggested with his potato analogy, we're witnessing the introduction of a genuinely new "crop" for humanity to harvest: one that doesn't require soil, doesn't depend on weather, and doesn't compete with existing agriculture. It's protein from a previously untapped dimension of our food system: the air itself, converted through ancient biological technology scaled by modern engineering.

For the supplement industry and health-conscious consumers, the implications are monumental. Whey-level protein quality with plant-level sustainability. Complete amino acids with naturally-high B12 and iron. Exceptional nutritional density in a single ingredient. And it's all possible because sometimes the most advanced technology isn't what we invent, it's what we discover in nature and learn to work with at scale.

Subscribe to PricePlow's news alerts to stay updated on Solein® and Solar Foods' developments:

Comments and Discussion (Powered by the PricePlow Forum)