The supplement industry is witnessing its most significant protein innovation since whey isolate revolutionized post-workout nutrition decades ago. But this time, the breakthrough comes from literally thin air.

Finnish company Solar Foods just made protein powder from literal air! Solein® uses microbes that eat hydrogen + CO2 to produce 78% protein with all essential amino acids. It's also already GRAS self-affirmed and in production.

Meet Solein®, a protein powder that fundamentally challenges everything we thought we knew about how protein gets made. While the industry has spent years debating plant versus animal sources, optimizing absorption rates, and perfecting flavor profiles, Finnish company Solar Foods quietly solved a much bigger problem: they figured out how to create complete protein without needing farms, animals, or even plants.

Out of Thin Air: A Sustainable Protein Source Unlike Any Other

Solein® represents the first commercially viable protein completely disconnected from agriculture. Instead of relying on crops that need months to grow, weather that needs to cooperate, or animals that require vast resources, Solar Foods uses hydrogen-oxidizing microbes that literally eats air molecules to produce protein in just 70 hours.

The technology sounds like science fiction, but the results are remarkably practical. Solar Foods has been producing Solein® at their Factory 01 facility in Finland since 2024, with regulatory approval already secured in Singapore and GRAS status obtained in the United States. This isn't a laboratory curiosity or a distant future possibility -- it's happening right now.

Solein® is revolutionary for several reasons that go beyond its unique production method. The environmental implications are monumental: this process uses 95% less land than traditional animal proteins and can be 20 times more efficient than plant-based alternatives. More importantly for our industry, it opens up entirely new possibilities for sustainable protein sourcing that could reshape how we think about nutrition and supplementation.

A Fermented Protein Source that Bests Plant-Based Protein's Amino Profiles... and it's non-GMO!

But here's what really matters: Solein® delivers a complete amino acid profile in a neutral-tasting powder that can seamlessly integrate into existing formulations. Solar Foods isn't asking consumers to sacrifice quality or taste for sustainability -- they're offering a genuinely superior solution that happens to solve some of humanity's biggest environmental challenges along the way.

The age of food and protein "out of thin air" has officially begun, and the implications extend far beyond just another ingredient option. This could be the technology that finally allows global protein production to scale without the environmental costs that have plagued traditional sources. It's even on the drawing board to be used as a food source for astronauts in outer space!

Ready to explore how non-GMO ancient microbes, electricity, and some very clever Finnish engineering might transform your next protein shake? Let's dive into the science, the sustainability, and the future implications of what might be the most important protein innovation of our lifetime. But before we do, sign up for our Solar Foods and Solein® news alerts -- you're not going to want to miss what this company has coming.

Subscribe to PricePlow's Newsletter and Alerts on These Topics

What is Solein®? The Science Behind Protein "Out of Thin Air"

To understand why Solein® is such a revolutionary leap forward, we need to examine the remarkable biology that makes it possible. While the "out of thin air" tagline captures the imagination, the reality involves a sophisticated microorganism that has been perfecting this process for millions of years.

The Biological Foundation

Single-cell organisms: At its core, Solein® is composed of dried hydrogen-oxidizing microbes (HOB) -- specifically, single-celled organisms that belong to a group of autotrophic microbes capable of creating their own food from inorganic compounds.[1] Solar Foods utilizes a specific strain from the Xanthobacter genus -- naturally occurring hydrogen-oxidizing microbes discovered in Finland's rich biodiversity. This non-GMO microbe is known for efficient protein synthesis, making it a perfect locally-sourced choice for a hydrogen-oxidizing organism for commercial protein production.

Solein® is Made From Non-GMO Microbes!

These aren't genetically modified organisms -- they're naturally occurring microbes that Solar Foods discovered in Finland's environment. As Susanna Mäkinen, Head of Biology at Solar Foods, explains: "The microbe at the heart of Solein®'s story was plucked from the rich biodiversity of Finland's nature. Little did it know that it would be the ancestor of trillions of similar yellow cells."

Chemosynthesis process: Unlike plants that rely on photosynthesis to convert sunlight into energy, Solein®'s microbes use a process called chemosynthesis. In this remarkable biological pathway, the microbes oxidize hydrogen gas, essentially removing electrons from hydrogen molecules, which releases energy.[2]

This energy powers the microbes' ability to fix carbon dioxide from the air, transforming it into organic compounds including complete proteins. The process requires no sunlight, making it independent of weather conditions and capable of operating 24/7 in controlled environments. This biological machinery enables the microbes to achieve CO2 reduction efficiencies that actually exceed natural photosynthesis.[2]

Fermentation vs. traditional yeast: The key distinction between Solein® and traditional fermented proteins lies in their feedstock requirements. Conventional yeast fermentation, whether for brewing, baking, or protein production, relies on sugar as its primary carbon and energy source. This sugar typically comes from crops like corn, wheat, or sugar cane, creating a dependency on agricultural land and resources.[3]

Solein®'s microbes eliminate this sugar dependency entirely. Instead, they consume gases that are abundant in our atmosphere: carbon dioxide, hydrogen (produced through water electrolysis using sustainable electricity), and oxygen. This fundamental difference means Solein® production is completely independent of crop agriculture: It doesn't compete for agricultural land, doesn't require specific weather conditions, and doesn't depend on harvest seasons.[4]

The fermentation process itself occurs in carefully controlled bioreactors where temperature, pH, and gas concentrations are precisely managed. This controlled environment allows for consistent, predictable production while eliminating contamination risks that can plague agricultural systems.

Biomass Fermentation vs. Precision Fermentation: A Critical Distinction

It's important to understand that Solein® uses biomass fermentation, not precision fermentation. This distinction fundamentally changes both the process and the end product. In biomass fermentation, the microbes themselves become part of the ingredient after pasteurization and drying, similar to how yeast becomes part of bread, beer, cheese, and yogurt during traditional fermentation processes. The entire microbial biomass is harvested as the final protein product, with no separation required.

Precision fermentation, used by companies like Perfect Day, operates differently: there, microbes (whether they're yeast, fungus strains, or bacteria) are genetically-modified using CRISPR and are fed substrates to produce specific proteins or compounds that are then separated from the microbial biomass. Solein® is not that! Such a process requires extensive downstream processing to isolate the desired product while the microbial biomass often becomes waste.

Solein®'s approach eliminates this complexity – the microbes are part of the product, making it a more efficient and waste-free process that mirrors humanity's oldest fermentation traditions.

Production Process Breakdown

The transformation from air molecules to protein powder involves four precisely orchestrated steps that occur in Solar Foods' Factory 01. This isn't theoretical manufacturing – it's a proven industrial process producing protein daily.

The distinctive golden color comes from Solar Foods' Xanthobacter microbes -- the same non-GMO organisms that convert hydrogen and CO2 into nutritious protein. Lab technicians regularly sample the protein powder to ensure consistent quality and that characteristic creamy texture with subtle umami notes.

-

Water electrolysis

The process begins with renewable electricity splitting water (H2O) into its component gases: hydrogen and oxygen. This electrolysis step is the energy-intensive foundation of the entire system, requiring approximately 18-30 kWh per kilogram of final biomass produced.[5] Solar Foods emphasizes using renewable electricity for this step, making the entire process carbon-neutral when powered by clean energy sources.

The electrolysis occurs in specialized units designed for high efficiency, with alkaline electrolysis technology achieving industry-leading system efficiencies. The hydrogen and oxygen produced are then fed directly into the fermentation system, eliminating the need for gas storage and transportation.

-

Gas fermentation

Inside continuous stirred-tank bioreactors with volumes reaching 200 m3, the hydrogen-oxidizing microbes consume their carefully balanced gas diet. The typical gas ratio is CO2:O2:H2 at 1:2:7 volumetric proportions, creating optimal conditions for microbial protein synthesis.[5]

The microbes also receive a water-based mineral medium containing essential nutrients: ammonium as a nitrogen source, plus inorganic salts with sulfur, phosphorus, magnesium, sodium, potassium, iron, and calcium. Trace elements including manganese, zinc, molybdenum, cobalt, nickel, and copper are added in minor amounts.[1]

Temperature, pH, and gas concentrations are precisely controlled throughout the fermentation, with phosphoric acid and sodium hydroxide used to maintain optimal pH levels. This controlled environment allows the microbes to achieve hydrogen conversion efficiencies that go beyond 90%, which bests earlier research from even a decade ago.[5]

-

Harvesting

The protein fortifies pasta with complete amino acids while maintaining the authentic flavor profile consumers expect -- no masking agents or flavor systems needed.

Here's where Solein®'s speed advantage makes the process into a true scientific marvel: The continuous cultivation process means fresh protein is ready for harvest every 70 hours in an uninterrupted cycle that never stops producing! To put this in perspective, spring wheat requires 100-130 days to grow, winter wheat needs 180-250 days, and egg-laying hens don't even begin producing protein until they're five months old.

Every Day is a Harvest Day

This rapid turnaround means Factory 01 operates on what Solar Foods calls "every day is a harvest day" -- continuous production regardless of seasons, weather, or agricultural cycles. The bioreactor produces the same daily protein output as 300 dairy cows, but without the environmental impact or resource requirements.

-

Processing

After cultivation, the microbial broth undergoes heat treatment, concentration and drying.[1] First, the broth is pasteurized by heating with recovered heat, ensuring food safety while maintaining nutritional integrity. The pasteurized broth then proceeds to separation, where continuous centrifugal separation removes the liquid supernatant (the liquid portion separated from the cells) from the concentrated microbial biomass. The supernatant is sent to wastewater treatment, while the concentrated cell slurry (now containing the protein-rich microbes) moves to the final drying stage.

A drum dryer, heated with low-pressure steam, removes the remaining water from the product. The final result is Solein®: a flour-like powder that's 78% protein, ready for incorporation into food products.[1]

The entire facility requires regular cleaning using a cleaning-in-place (CIP) system about four times per year, involving sodium hydroxide and nitric acid solutions to maintain sterility and food safety standards.

With the final step complete, we can now look at the resulting nutritional profile:

Nutritional Profile: A Protein That Rivals Whey

When Solar Foods claims Solein® delivers "unmatched value", the nutritional data backs up that bold statement. At 78% protein by dry weight, Solein® doesn't just compete with traditional protein sources, it often surpasses them in key metrics that matter most to serious athletes and health-conscious consumers.

The complete amino acid profile sets Solein® apart immediately. With 43% essential amino acids -- matching whey protein exactly -- Solein® provides all nine amino acids the human body cannot synthesize on its own. Even more impressive is the 20% branched-chain amino acid (BCAA) content, putting it in elite company alongside whey (24%) while significantly outperforming plant-based alternatives like pea protein (17%) or rice protein (15%).

Solein®'s Complete Macronutrient Breakdown:

- 78% protein with all essential amino acids

- 10% dietary fiber (40% of which are beneficial beta-glucans)

- 6% unsaturated fats (primarily heart-healthy oleic acid)

- 2% carbohydrates

- 4% minerals and vitamins

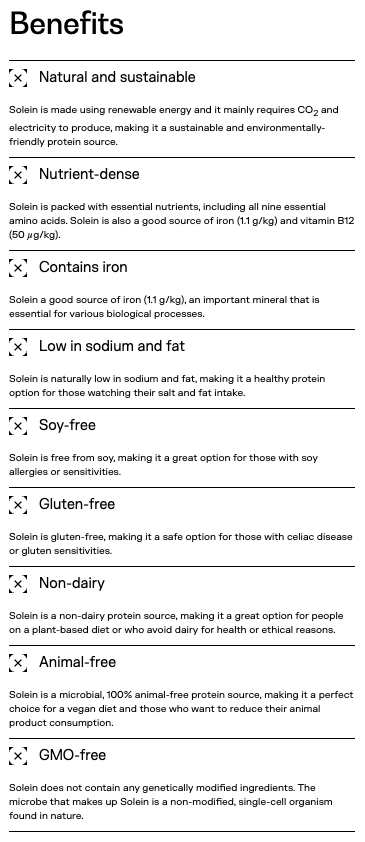

Solein® combines the best nutritional aspects of both animal and plant proteins while eliminating their respective drawbacks. You get whey-level amino acid completeness without the cholesterol or saturated fats! You get plant-level fiber content without the anti-nutritional factors or digestive issues that plague many plant proteins.

Micronutrient Powerhouse: Note the Iron, B12, and Calcium Levels

Solein®'s micronutrient profile reads like a carefully designed supplement stack. The iron content hits 110mg per 100g, making it naturally high in this crucial mineral that women often struggle to get adequate amounts of. Compare this to whey protein's 0.3mg, and the difference becomes stark.

The vitamin B12 content at 5 micrograms per 100g is another significant advantage, especially for individuals following plant-based diets or anyone concerned about B12 deficiency. Most plant proteins contain zero B12, requiring separate supplementation, while Solein® delivers meaningful amounts naturally.

Additional minerals include 110mg calcium per 100g, matching soy protein and providing essential support for bone health. The complete mineral profile supports not just protein synthesis but overall metabolic function.

The PDCAAS Perfect Score

Perhaps most importantly, Solein® achieves a theoretical Protein Digestibility-Corrected Amino Acid Score (PDCAAS) of 1.0, which is the highest possible protein quality assessment rating. This puts it in the same elite category as whey protein and whole eggs, meaning the body can effectively utilize nearly all of the amino acids Solein® provides.

This "perfect" PDCAAS score becomes even more impressive when you consider that most plant proteins fall short: pea protein scores 0.82-0.93, rice protein manages only 0.47-0.60, and even soy protein typically ranges from 0.9-1.0. Solein® delivers animal-protein-level utilization without any of the environmental or ethical concerns.

Functional Fiber Content

The 10% dietary fiber content, with 40% of that being beta-glucans, adds significant functional value beyond basic protein delivery. Beta-glucans are well-researched for their cholesterol-lowering effects and immune system support, typically found in oats and certain mushrooms but rare in protein powders.

This fiber content helps with satiety, digestive health, and blood sugar management, turning Solein® into more than just a protein source. It becomes a functional food ingredient that can improve the overall nutritional profile of any product it's added to.

Taste Profile: The Flavor Advantage

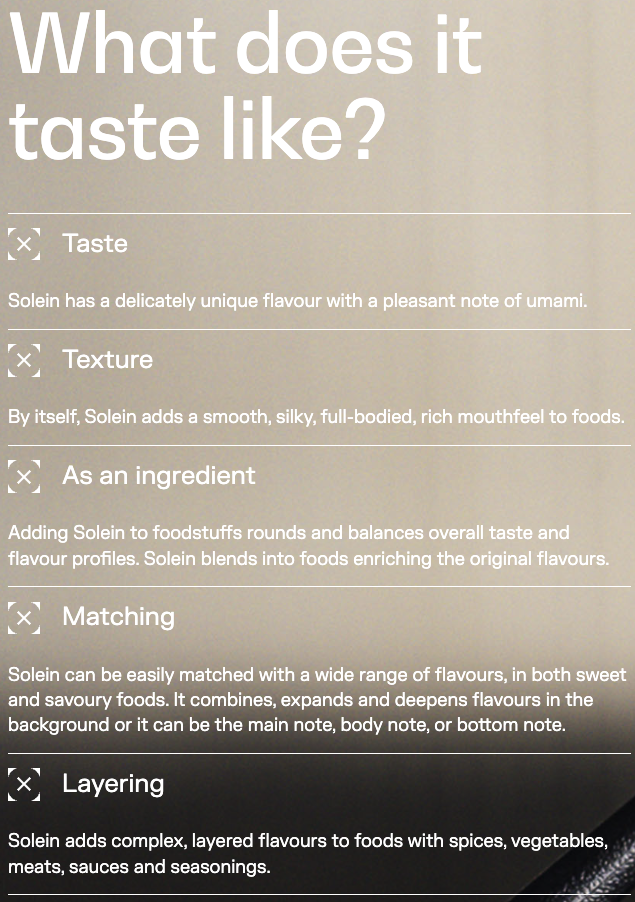

While nutrition matters, taste often determines real-world adoption. Solein® delivers what Solar Foods describes as a "creamy mouthfeel with slight nutty flavor". This is a profile that allows it to "vanish into foods" without the off-notes that plague many plant proteins.

This makes for a major advantage over alternatives like pea protein (earthy with bitterness and gritty texture) or soy protein (beany with chalky aftertones and concerns of estrogenicity). The neutral taste profile means formulators can achieve high protein content without compromising flavor, while consumers get effective nutrition without the sensory compromises typically required with sustainable protein sources.

The result is a protein source that doesn't ask consumers to choose between nutrition quality, sustainability, and functionality – it delivers on all three fronts simultaneously.

The Environmental Revolution: Solein® vs. Traditional Proteins

The numbers don't lie, and when it comes to environmental impact, Solein® doesn't just compete with traditional protein sources... it completely redefines what's possible.

Life Cycle Assessment Data

Based on the comprehensive 2021 study by Järviö et al, the environmental advantages of Solein® become immediately apparent when examined through an life cycle assessment.[1] This peer-reviewed analysis provides the first empirical data on Solein®'s environmental footprint, moving beyond theoretical projections to real-world measurements from Solar Foods' production facility.

-

Land use

The land efficiency gains are incredible: Solein® requires 95% less land than animal proteins while achieving 20 times more efficiency than plant-based alternatives.[1] To put this in perspective, producing one kilogram of Solein® protein requires virtually no agricultural land, while beef cattle demand extensive grazing areas and feed crop cultivation spanning thousands of square meters.

-

Water consumption

Traditional protein production is notoriously water-intensive, with beef requiring approximately 15,000 liters per kilogram of protein. Solein®'s water requirements are dramatically lower, utilizing only the water needed for electrolysis and basic processing and cleaning operations. The closed-loop system recycles water throughout the production process, eliminating the massive freshwater demands that plague conventional agriculture.

-

Carbon efficiency

When powered by Finland's abundant renewable electricity, Solein® demonstrates excellent production efficiency with significantly lower CO2 emissions than traditional protein sources.[1] The controlled production environment achieves remarkable efficiency: Solein® generates just 1.57 kg CO2-equivalent per kilogram of protein when using renewable energy, compared to beef production estimated at 204.33 kg and dairy production at 172.87 kg CO2-equivalent per kilogram of protein.

This efficiency advantage stems from the streamlined production process that eliminates the extensive supply chains, transportation, and processing steps required for traditional protein sources.

-

Energy considerations

While Solein® requires significant electricity input (18-25 kWh per kilogram of biomass), this energy demand becomes environmentally neutral when sourced from renewable sources,[5] of which Finland has abundant amounts. Further, this electricity replaces the massive, distributed energy costs embedded in traditional agriculture, from fuel for tractors and transport to fertilizer production and livestock feed processing and storage.

Sustainability Metrics

Solar Foods isn't done yet:

-

Resource Independence

Perhaps the most revolutionary aspect of Solein® production is its complete independence from agricultural systems. Unlike every other protein source currently available, Solein® requires no agricultural land, weather cooperation, or specific climate conditions. Factory 01 operates continuously regardless of seasons, droughts, floods, or temperature extremes that routinely disrupt global food production.

This independence extends beyond weather resilience. Solein® production doesn't compete with food crops for fertile land, doesn't require specific soil conditions, and doesn't depend on agricultural chemicals or pesticides. The technology fundamentally disconnects protein production from the environmental variables that make traditional agriculture increasingly vulnerable to climate change.

-

Scalability and Location Independence

The location-agnostic nature of Solein® production opens up unprecedented possibilities. The technology can be deployed in deserts, Arctic regions, and even outer space – anywhere electricity and basic infrastructure can be established.[6] Solar Foods has already demonstrated this potential by being the international winner of NASA's Deep Space Food Challenge, developing concepts for astronaut nutrition during Mars missions.

This scalability isn't theoretical. Desert installations could leverage abundant solar energy for renewable electricity while avoiding competition for arable land. Arctic deployments could provide local protein production in food-insecure regions. Urban installations could bring protein production directly to population centers, eliminating transportation-related emissions.

We'll be covering the applications for outer space in greater detail later on.

-

Energy Efficiency Over Photosynthesis

The biological machinery powering Solein® achieves efficiency levels that make photosynthesis look primitive by comparison. Hydrogen-oxidizing bacteria demonstrate 20 times higher efficiency than natural photosynthesis and approximately 200 times more efficiency than meat production.[6]

This efficiency advantage stems from the elimination of biological inefficiencies inherent in traditional food production. Plants must dedicate significant energy to structural components like cellulose that humans can't digest. Animals require massive feed inputs to maintain basic metabolic functions before producing edible protein. Solein®'s microbes, by contrast, channel nearly all their energy directly into protein synthesis, achieving conversion efficiencies that approach theoretical maximums.

The environmental revolution pioneered by Solar Foods extends beyond simple efficiency gains. It fundamentally decouples protein production from the planetary resource constraints that threaten global food security. While traditional agriculture increasingly competes for land, water, and climate stability, Solein® offers a pathway to abundant protein that actually reduces pressure on these critical resources.

Regulatory Status and Safety Profile

The path from laboratory innovation to consumer plates (or shaker cups) requires navigating numerous complex regulatory frameworks designed to ensure food safety. Solar Foods has systematically approached this challenge, securing approvals in key markets while building comprehensive safety documentation that positions Solein® for global acceptance.

Current Approvals

As of June 2025, the following has been established:

-

United States (2024)

Solar Foods achieved a significant milestone in September 2024 by obtaining self-affirmed GRAS (Generally Recognized As Safe) status for Solein® in the United States. This designation allows Solar Foods to market Solein® as a food ingredient without requiring pre-market approval from the FDA, provided they can demonstrate that qualified experts generally recognize the ingredient as safe under the conditions of its intended use.

This self-affirmed status reflects Solar Foods' confidence in their comprehensive safety database and the ingredient's established safety profile based on extensive testing and evaluation by an independent panel of established scientists.

-

Singapore (2022)

Solein® made history by receiving its first novel food regulatory approval in 2022 from the Singapore Food Agency (SFA), marking the first time any protein produced entirely from air and electricity gained commercial food approval anywhere in the world. This groundbreaking approval allows for the import, manufacture, and sale of food products containing Solein® throughout Singapore.

Singapore's approval wasn't just a regulatory checkbox: It represented a watershed moment for cellular agriculture and alternative proteins. As Solar Foods CEO Pasi Vainikka noted, "I'd compare this to the discovery of the potato: we are introducing an entirely new ingredient to the world of food." The SFA's rigorous novel food assessment process included comprehensive evaluation of production methods, nutritional composition, safety data, and intended uses.

-

Pending markets

Solar Foods has strategically filed novel food dossiers in the European Union and United Kingdom, with EU approval estimated for 2026. These submissions represent the next phase of global market access, targeting regions with sophisticated regulatory frameworks and strong demand for sustainable protein alternatives.

The EU novel food regulation requires comprehensive safety documentation similar to Singapore's rigorous assessment, including detailed production process descriptions, compositional analysis, nutritional assessment, toxicological studies, and allergenicity evaluation. However, the EU's more complex bureaucratic processes typically extend approval timelines significantly beyond other jurisdictions. Solar Foods' proactive approach in these markets demonstrates their commitment to navigating diverse regulatory pathways while maintaining consistent safety standards.

Quality control

The controlled environment in Solar Foods' Factory 01 enables continuous monitoring and sterile conditions throughout the production process. Unlike agricultural systems exposed to soil pathogens, erratic weather, animal waste, pests, countless endocrine-disrupting pesticides, and other contamination risks, Factory 01 operates as a closed system with comprehensive quality assurance.

The facility also incorporates cleaning-in-place (CIP) systems requiring 120°C heat to maintain sterility. Pasteurization occurs at much lower temperatures to ensure food safety while preserving nutritional integrity.[1] Temperature, pH, and gas concentrations undergo real-time monitoring with automated adjustments to maintain optimal production conditions.

This level of process control enables consistent protein quality and composition – something nearly impossible to achieve with agricultural systems subject to seasonal variations, weather fluctuations, and biological variability. Factory 01 provides manufacturing-level precision applied to biological protein production, setting new standards for reliability and consistency in food production.

Safety Considerations

The regulatory successes indicate how serious Solar Foods is regarding safety and toxicity concerns:

-

Toxicity Studies

Solar Foods has completed comprehensive safety assessments that meet international standards for novel food ingredients. These studies encompass acute toxicity testing, sub-chronic feeding trials, and genotoxicity screening -- the gold standard battery of tests required for regulatory approval of new food ingredients.

The safety evaluation process included both in vitro and in vivo studies designed to identify any potential adverse effects from Solein® consumption. Results consistently demonstrated no toxicological concerns at intended use levels, supporting the ingredient's safety profile for human consumption. This extensive toxicological database provided the foundation for regulatory submissions across multiple jurisdictions.

-

Allergen profile (or Lack Thereof)

One of Solein®'s significant safety advantages is the absence of common food allergens. Unlike many traditional protein sources, Solein® contains no dairy, eggs, peanuts, tree nuts, soy, wheat, fish, or shellfish – the eight major allergens responsible for the vast majority of food allergic reactions.

This profile represents a major advantage for food manufacturers seeking to create inclusive products that don't require allergen labeling or cross-contamination concerns. The protein's microbial origin eliminates the complex allergenic proteins found in agricultural crops and animal products, making it suitable for individuals with multiple food sensitivities.

-

Shelf Life / Stability

Solar Foods has reported that Solein® has a shelf-life of 24 months (two years), putting it on par with other protein sources.

The combination of rigorous regulatory approvals, comprehensive safety testing, composition with no major allergens, and sterile production methods positions Solein® as one of the most thoroughly-vetted and controlled protein ingredients entering the market. As regulatory frameworks evolve to accommodate cellular agriculture innovations, Solar Foods' proactive safety approach establishes the standard for next-generation protein ingredients.

Applications and Functional Properties

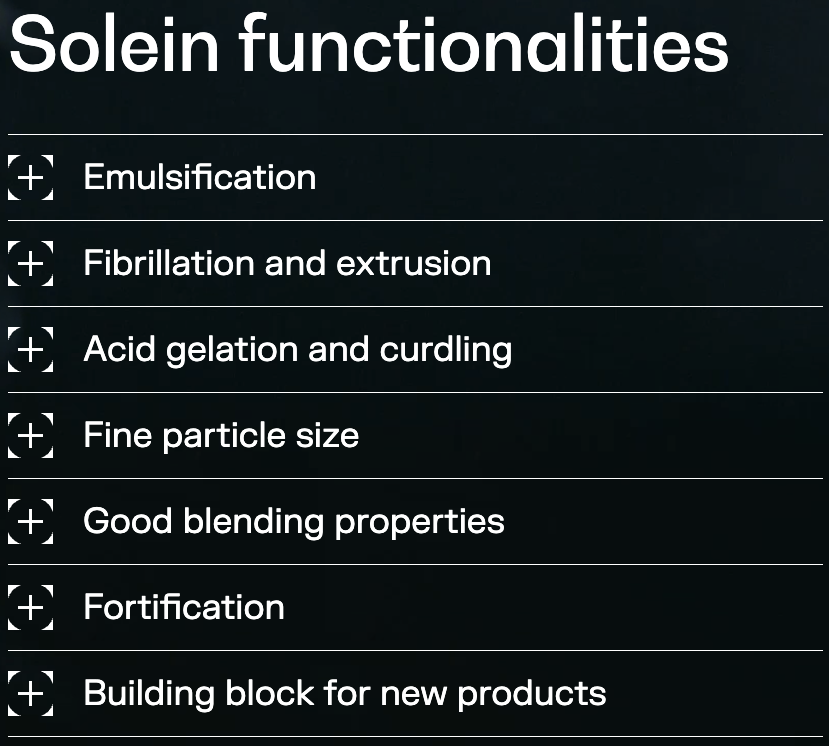

While Solein®'s revolutionary production method captures headlines, its real-world value lies in seamless integration across food categories. Solar Foods has developed what they describe as an "all-purpose protein" that adapts to virtually any application while delivering superior functionality compared to traditional alternatives.

Food Industry Integration

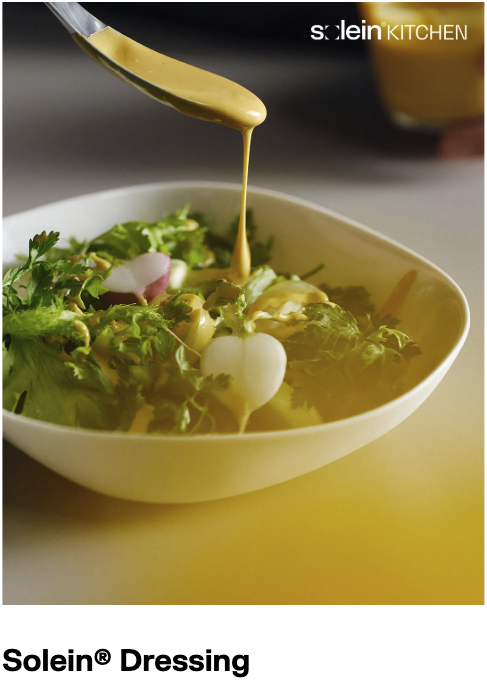

- Neutral taste: Perhaps Solein®'s most commercially valuable characteristic is its ability to "vanish into foods" without altering familiar flavor profiles. Solein® delivers what Solar Foods describes as a "delicately unique flavor with a pleasant note of umami." The protein enhances existing flavors rather than masking them, allowing food manufacturers to achieve high protein content without the sensory compromises typically required with sustainable alternatives.

This flavor neutrality becomes a significant competitive advantage when formulating consumer products. Where pea protein might require additional masking agents or flavor systems and has a nagging gritty texture, Solein® integrates cleanly, reducing formulation complexity and ingredient costs while maintaining clean label appeal.

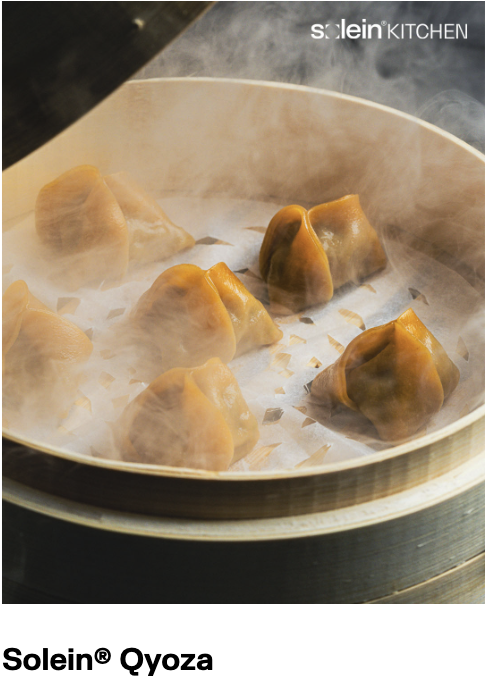

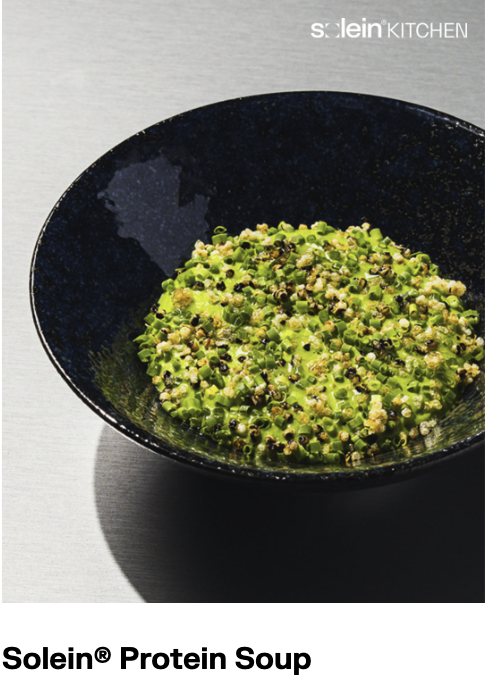

- Functional versatility: Solar Foods has successfully demonstrated Solein® across five major food categories, each requiring different functional properties. In alternative dairy applications like ice cream, yogurts, and cheese alternatives, Solein® provides the protein structure and creamy mouthfeel that consumers expect. The protein's natural umami characteristics enhance the rich, satisfying taste profile that plant-based dairy products often struggle to achieve.

- For meat alternatives, Solein® offers complete amino acid profiles that match animal proteins while providing the functional binding and texture-building properties essential for realistic meat analogues. The protein's fine powder form enables smooth integration into ground meat applications, sausages, and formed products.

- In pasta and baked goods, Solein® functions as both a protein fortification ingredient and an egg replacement system. The protein's binding properties support dough structure while its neutral color maintains the visual appeal of traditional wheat-based products.

- Beverage applications benefit from Solein®'s excellent solubility and clean taste, enabling high-protein drinks without the chalky mouthfeel common with plant proteins.

- Culinary specialties including soups, dressings, seasonings, and sauces may turn out to be the most demanding application area, where any off-flavor becomes magnified and consumers are growingly tired of excessive industrially-processed seed oils. Solein®'s ability to enhance rather than compete with complex flavor systems makes it ideal for premium culinary applications.

- Processing stability: Unlike many alternative proteins that denature or lose functionality during processing, Solein® maintains its integrity through various manufacturing processes. The protein withstands the thermal processing required for shelf-stable products, the pH variations in fermented foods, and the mechanical stresses of extrusion and forming operations. This processing stability reduces manufacturing complexity and ensures consistent end-product quality.

Concepts in Partnership with Sensapure Flavors

Solar Foods has partnered with Sensapure Flavors, the industry's top-tier flavor house, to develop optimized flavor systems that showcase Solein®'s versatility across applications. This collaboration enables brands and manufacturers to experience properly formulated Solein® products at tradeshows and development meetings, accelerating commercial adoption by demonstrating the ingredient's true potential when expertly formulated. They're available for brands and at tradeshows from either company.

Supplement Industry Potential

As a protein source (delivering 43% essential amino acid content and 20% BCAA content), Solein® provides the leucine, isoleucine, and valine crucial for muscle protein synthesis that the sports and active nutrition industry demands. Its clean label appeal appeals to an industry increasingly focused on transparency and sustainability, with a single ingredient: Solein®. The sustainability angle becomes increasingly important as supplement users -- especially in vegan/vegetarian demographics -- seek products that align with their values.

From a technical standpoint, Solein® offers several advantages for supplement formulators. The fine powder form ensures smooth mixing and excellent dispersibility, eliminating the grittiness that plagues many plant proteins. The neutral taste profile allows for creative flavor development without the masking challenges associated with pea or hemp proteins.

The natural iron content at 110mg per 100g and vitamin B12 at 5 micrograms per 100g add functional nutrition benefits for women and plant-based dieters that eliminate the need for separate mineral and vitamin fortification.

Extreme Applications: Space and Beyond

Perhaps the most wild demonstration of Solein®'s versatility comes from its selection as a NASA Deep Space Food Challenge winner in 2024. The competition sought innovations capable of feeding astronauts during three-year Mars missions, where resupply is impossible and every gram of weight matters.

Solar Foods' space application concept envisions a 40-liter bioreactor providing daily protein content for six astronauts during long-term space missions. The closed-loop system not only produces protein but releases oxygen as a byproduct, contributing to life support systems. This extreme application validates Solein®'s potential for deployment in the harshest environments imaginable. After all, if it works in space, it can work anywhere on Earth.

Solein®: The Future of Protein is Here

We stand at a pivotal moment in the history of not just protein, but food production altogether. While the supplement industry has spent decades optimizing extraction methods, improving flavors, and perfecting amino acid profiles within existing protein sources, Solein® brings something fundamentally different: a complete reimagining of how protein gets made.

Key Points to Take Away:

- Solein® represents a fundamental shift in protein production methodology. This isn't another plant protein or even another fermentation process -- it's the first protein source completely disconnected from agriculture. Factory 01 proves that high-quality, protein can be produced from ingredients derived from air and renewable electricity, scaling production methods that surpass natural photosynthesis by orders of magnitude.

- Environmental benefits are substantial and scientifically validated. The peer-reviewed research from Järviö et al. demonstrates environmental impacts that aren't just lower than traditional proteins... they're in a different category entirely. With 95% less land use than animal proteins and 20 times higher efficiency than plant alternatives, Solein® offers the first truly sustainable protein source that can scale to meet global demand without competing for planetary resources.

- Commercial viability is already here with Factory 01. Unlike many alternative proteins that remain in pilot phases or struggle with cost-effectiveness, Solein® is already in commercial production. The 70-hour production cycle and continuous operation prove this technology works at industrial scale right now, not in some theoretical future.

- Regulatory acceptance is growing globally. With GRAS status obtained in the United States and novel food approval in Singapore, Solein® has cleared the regulatory hurdles that often delay or prevent alternative protein adoption. The comprehensive safety testing, no major allergens, and sterile production process position Solein® for regulatory approval in additional markets.

- Future implications extend far beyond just another protein powder. As Solar Foods co-founder Pasi Vainikka noted, "I'd compare this to the discovery of the potato: we are introducing an entirely new ingredient to the world of food." Solein® opens possibilities for protein production in deserts, urban centers, Arctic regions, and even space installations. It represents the beginning of location-independent, weather-independent, agriculture-independent protein production.

There's a Bigger Story Here

The broader implications reshape how we think about food security, environmental sustainability, and global protein supply chains. If protein can be produced anywhere electricity and basic infrastructure exist, the geopolitical implications alone are staggering. Protein-importing nations could achieve food security independence. Urban centers could produce their own protein supplies. Remote locations could access high-quality nutrition without complex supply chains.

For the supplement industry specifically, with Solein®, Solar Foods has pioneered the first protein source that eliminates traditional trade-offs. Brands and formulators no longer need to choose between sustainability and performance, between clean label and complete amino acids, between environmental responsibility and superior taste. Solein® delivers on all fronts simultaneously.

The Future Has Officially Arrived

The protein revolution is happening now, not in some distant future. Factory 01 is producing Solein® today. Regulatory approvals are expanding. Commercial partnerships are forming. The question isn't whether protein "out of thin air" will transform the industry -- it's how quickly brands and consumers will embrace this paradigm shift.

Follow PricePlow to stay informed about Solein®'s market entry and consider its potential role in sustainable nutrition. For supplement brands, this is a new opportunity to differentiate with genuinely superior sustainability credentials while maintaining or improving product performance. For consumers, it offers a pathway to support dairy-free, non-GMO, vegan-friendly nutrition without compromising on effectiveness.

The age of food "out of thin air" has officially begun. The only question is whether you'll be among the early adopters who recognize this transformation or wait for the rest of the industry to catch up.

Comments and Discussion (Powered by the PricePlow Forum)