Juan Benítez-García and Sini Möttönen from Solar Foods reveal how ancient Finnish microbes and renewable electricity create Solein®, the revolutionary protein made "out of thin air" on Episode #175 of the PricePlow Podcast.

On Episode #175 of the PricePlow Podcast, we sit down with Juan Benítez-García, Chief Sales Officer, and Sini Möttönen, Senior Application Scientist from Solar Foods at IFT First 2025 in Chicago. Broadcasting from the Sensapure Flavors booth, we explore the revolutionary Solein® protein that's literally made "out of thin air".

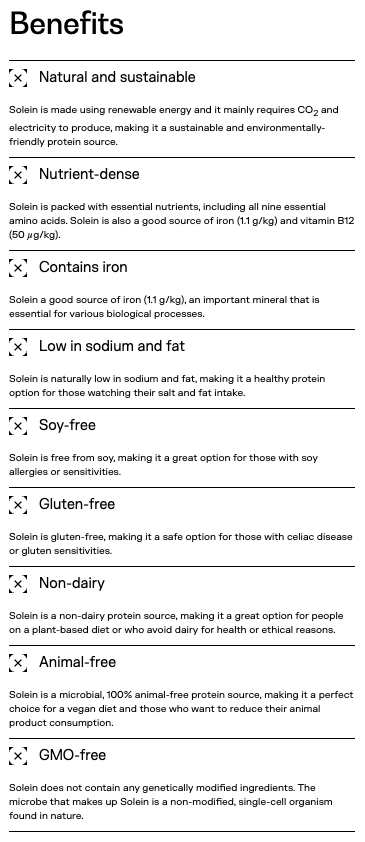

This isn't your typical alternative protein story. Solar Foods has achieved what seemed impossible: creating complete, high-quality protein without farms, animals, or even plants. Using ancient Finnish microbes and renewable electricity, they've developed a process that bypasses photosynthesis entirely, producing protein that's 80% pure with a complete amino acid profile including 20% BCAAs. The result is a golden-colored powder with exceptional nutritional density, including naturally high levels of iron and vitamin B12.

Our conversation reveals how biomass fermentation differs from precision fermentation, why Solein® tastes creamy with subtle nutty notes, and how this technology earned NASA recognition for feeding astronauts on Mars missions. From ice cream to protein bars, Juan and Sini demonstrate the versatility of this groundbreaking ingredient while explaining why it represents a fundamental shift toward sustainable, location-independent protein production.

Subscribe to the PricePlow Podcast on Your Favorite Service (RSS)

https://blog.priceplow.com/podcast/solar-foods-solein-175

Video: Solar Foods Brings Protein “Out of Thin Air” to IFT First 2025

Podcast: Play in new window | Download (Duration: 1:09:31 — 72.0MB)

Detailed Show Notes: The Science and Future of Air-Based Protein

-

0:00 - Introductions: Meeting the Solar Foods Team at IFT First

Mike and Ben welcome listeners from IFT First 2025 in Chicago, broadcasting from the Sensapure Flavors booth. Today's conversation focuses on Solar Foods and their revolutionary Solein® protein ingredient.

Juan Benítez-García, Chief Sales Officer at Solar Foods, brings over 15 years of experience in novel protein ingredients, having worked across dairy, plant-based, and innovative protein categories. His role involves driving the commercialization of Solein® and bringing this completely new protein source to market.

Sini Möttönen, Senior Application Scientist at Solar Foods, has been with the company for four years and brings additional food science product development experience. As someone passionate about sports nutrition, Sini became particularly excited when she learned about Solein®'s impressive amino acid profile, especially its 20% branched-chain amino acid content with leucine as the dominant BCAA.

The setting at Sensapure's booth is particularly fitting, as the two companies have partnered to develop flavor applications that showcase Solein®'s versatility in ready-to-drink beverages, ready-to-mix protein powders, and various food applications. This collaboration demonstrates how Solein® can be optimized for consumer taste preferences while maintaining its exceptional nutritional profile.

-

9:00 - The Science Behind Solein®: How Protein Gets Made from Air

Juan explains the fundamental innovation behind Solein®'s production process, which represents a complete departure from traditional protein manufacturing. The process begins with water electrolysis, where renewable electricity splits water molecules into hydrogen and oxygen. This hydrogen becomes the primary energy source for Solar Foods' proprietary microorganisms.

Finnish company Solar Foods just made protein powder from literal air! Solein® uses microbes that eat hydrogen + CO2 to produce 78% protein with all essential amino acids. It's also already GRAS self-affirmed and in production.

The carbon dioxide comes directly from the atmosphere, while essential minerals that the microbe naturally requires are provided through media preparation. These include nitrogen, phosphorus, sulfur, and trace elements that mirror what the microorganisms would consume in their natural Finnish environment where Solar Foods originally discovered them.

The fermentation process occurs in controlled bioreactors where these ancient microbes consume the hydrogen, carbon dioxide, and minerals over a 72-hour cycle. Unlike traditional fermentation that requires sugar feedstocks from agricultural crops, Solein®'s microbes perform chemosynthesis - essentially eating air molecules to produce protein. This process is five to ten times more efficient than photosynthesis, the biological foundation of all current food production.

After fermentation, the microbial biomass undergoes homogenization and pasteurization to ensure food safety. The final step involves drying the material into a flour-like powder that's approximately 80% protein. Juan emphasizes that this entire process occurs under one roof at Solar Foods' Factory 01 in Finland, providing unprecedented traceability and control compared to traditional protein supply chains that cross oceans multiple times before reaching consumers.

-

13:00 - Biomass vs. Precision Fermentation: Understanding the Key Difference

Mike asks for clarification about Solar Foods' fermentation approach, referencing recent conversations about precision fermentation companies like Helena and their lactoferrin production. Juan explains this critical distinction that many people misunderstand in the alternative protein space.

Precision fermentation involves genetically modifying microorganisms (often yeast) to produce specific proteins, which are then separated from the microbial biomass in downstream processing. The microbes essentially become protein factories, producing the desired compound while the biomass itself becomes waste. This approach requires extensive separation and purification steps.

Biomass fermentation, Solar Foods' approach, treats the entire microorganism as the final product. After pasteurization and drying, the complete microbial biomass becomes Solein® - nothing is separated or discarded. Juan compares this to traditional fermented foods like beer, bread, cheese, and yogurt where the microorganisms become part of the final product consumers eat.

This distinction is crucial because biomass fermentation eliminates complex downstream processing, reduces waste, and maintains the complete nutritional profile that the microbes naturally produce. The microbes aren't genetically modified - they're using the same biological processes they've employed in Finnish nature for millions of years, just scaled up in controlled bioreactors.

The efficiency advantage becomes apparent when considering waste streams. Precision fermentation generates significant microbial waste after protein extraction, while Solar Foods' process produces only water as a byproduct, which gets recycled back into the system.

-

18:00 - Nutritional Profile: Why 80% Protein Changes Everything

Sini dives into Solein®'s impressive nutritional composition, starting with the 80% protein content that immediately sets it apart from most protein sources. This high protein density means formulators can achieve target protein levels with smaller serving sizes, improving product economics and consumer convenience.

The amino acid profile excites Sini from a sports nutrition perspective. Solein® contains 43% essential amino acids - matching whey protein exactly - and 20% branched-chain amino acids (BCAAs). Leucine comprises the largest portion of the BCAAs, which is crucial for muscle protein synthesis and recovery applications.

Beyond protein, Solein® delivers a complete nutritional package. The ingredient naturally contains antioxidants and carotenoids that provide the distinctive golden color - these aren't added during processing but represent compounds the microbes produce for their own growth and survival. This includes naturally occurring beta-carotene and other beneficial plant-like compounds.

The mineral profile offers advantages for specific demographics. Solein® contains significant levels of naturally occurring iron and calcium, addressing common nutritional gaps especially relevant for women. Most importantly, it provides vitamin B12, which is typically absent from plant-based proteins and requires separate supplementation for vegans and vegetarians.

Juan emphasizes that Solein® combines the best nutritional aspects of both animal and plant proteins while eliminating their respective drawbacks. You get whey-level amino acid completeness without lactose, and plant-level sustainability without anti-nutritional factors or digestive issues common with legume proteins.

-

29:00 - Flavor Innovation: Partnering with Sensapure for Taste Excellence

The conversation turns to flavor development, highlighting the partnership between Solar Foods and Sensapure Flavors. Sini explains that developing optimal flavors requires understanding regional taste preferences, which is why Solar Foods chose to work with Sensapure's expertise in American market flavor development rather than trying to create US-targeted flavors from their Finnish headquarters.

Learn about flavors with Sensapure. Mike and Ben with Scott Zimmerman and Derek Greer of Sensapure Flavors in Episode #149, exploring the art and science of flavor creation in supplements and energy drinks.

During collaborative flavor development sessions, the teams discovered that Solein®'s creamy mouthfeel pairs exceptionally well with fresh, bright flavor profiles. This led to the creation of the "velvet lemon" concept, which combines Solein®'s natural creaminess with vibrant citrus notes that American consumers find appealing.

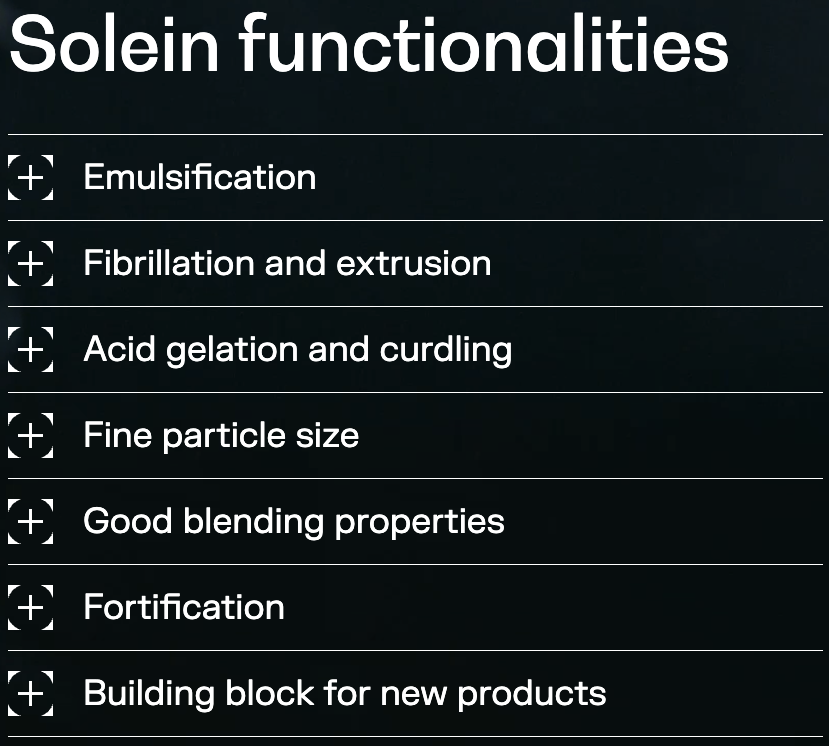

The emulsification properties of Solein® enable it to create rich, satisfying textures in beverages and foods. When oils are incorporated into Solein®-based formulations, the protein naturally emulsifies these fats, creating smooth, creamy products without requiring additional emulsifiers or stabilizers.

Sensapure's role extends beyond flavor creation to complete formulation support. They help determine optimal ratios of Solein® to other ingredients, identify complementary flavor systems, and ensure that finished products meet consumer expectations for taste, texture, and overall eating experience.

For products requiring extended shelf life (six months or longer), some formulations may incorporate stabilizers, but these decisions depend on specific product requirements and processing conditions. The partnership allows brands to access fully optimized Solein® formulations rather than having to develop applications from scratch.

-

34:00 - Versatile Applications: From Ready-to-Mix to Ice Cream

Sini describes Solein®'s exceptional water solubility and mixing properties, which make it ideal for ready-to-mix applications. The protein dissolves completely in cold water within 30 seconds, creating smooth, milkshake-like textures without the grittiness that plagues many plant proteins. This solubility advantage eliminates the need for specialized blending equipment or extended mixing times.

The color characteristics initially presented formulation challenges but ultimately became an advantage. While Solein®'s natural golden color easily transforms into brown tones (perfect for chocolate applications), it also works beautifully with flavors that complement or incorporate the yellow hue. Sini mentions they've successfully created chocolate milkshake formulations that showcase the ingredient's versatility.

Ice cream applications represent one of Sini's favorite uses for Solein®. The protein provides excellent texture and mouthfeel while delivering complete nutrition. Both traditional ice cream and protein ice cream formulations benefit from Solein®'s natural creaminess and neutral flavor profile.

Mike notes the functional food aspect - Solein® serves dual purposes by providing both protein content and natural coloring, eliminating the need for separate color additives in many applications. This functional versatility simplifies ingredient lists while maintaining clean label appeal.

Pricing competitiveness is another advantage, with Solein® positioned competitively against whey protein pricing while delivering superior sustainability credentials and complete nutrition. The team has developed concepts ranging from smoothie applications to baked goods, with each application category requiring different optimization approaches. Sini mentions that their product development chef has created impressive fresh berry formulations that work well in both smoothies and frozen dessert applications.

-

43:00 - Protein Bar Innovation: Soft Texture That Lasts

The conversation explores Solein®'s performance in protein bar applications, where the ingredient offers significant advantages over traditional protein sources. Unlike many proteins that create dense, hard textures in bars, Solein® maintains a soft, enjoyable mouthfeel throughout the product's shelf life.

The distinctive golden color comes from Solar Foods' Xanthobacter microbes -- the same non-GMO organisms that convert hydrogen and CO2 into nutritious protein. Lab technicians regularly sample the protein powder to ensure consistent quality and that characteristic creamy texture with subtle umami notes.

This texture advantage stems from Solein®'s unique protein structure and water-binding properties. Traditional protein bars often become increasingly firm and difficult to chew as they age, but Solein®-based bars remain palatable and enjoyable even after extended storage periods.

The shelf life benefits extend beyond texture to overall product stability. Solein®'s controlled production environment and consistent composition enable more predictable shelf life performance compared to agricultural proteins that vary seasonally and geographically.

Processing methods for Solein® protein bars include both extrusion and various baking techniques. Each processing approach requires optimization to maximize Solein®'s functional properties, but the ingredient's versatility allows for successful applications across different manufacturing processes.

The product development for these applications comes from Solar Foods' internal team, demonstrating their commitment to building comprehensive application capabilities rather than simply supplying raw ingredients. This approach helps potential customers understand how to optimize Solein® in their specific products.

-

52:00 - Space Applications: NASA Recognition and Mars Mission Potential

Juan discusses Solar Foods' remarkable achievement in winning awards in NASA's Deep Space Food Challenge, which sought innovations for feeding astronauts during long-term space missions including Mars exploration. This recognition validates Solein®'s potential for deployment in the most extreme environments imaginable.

The space application concept envisions relatively compact bioreactor systems that could produce fresh protein during multi-year space missions. A 40-liter bioreactor could provide daily protein requirements for six astronauts, offering fresh nutrition capabilities where resupply is impossible and every gram of weight matters.

Beyond basic nutrition, the closed-loop system provides additional benefits for space missions. The fermentation process releases oxygen as a byproduct, contributing to life support systems. The system can potentially utilize carbon dioxide from crew respiration and water from waste processing, creating a circular resource utilization system perfect for space applications.

The extreme environment capabilities extend beyond space to terrestrial applications. Solein® production systems could operate in deserts, Arctic regions, submarines, and military bases - anywhere basic infrastructure and electricity can be established. This location independence represents a fundamental shift in food production capabilities.

Juan shares an anecdote about discussing Solein® with a relative who participated in a 12-month sailing regatta, where weight considerations for food storage significantly impact performance. The ability to produce fresh protein on-board rather than carrying heavy food supplies could provide competitive advantages in such applications.

Mike asks about Solar Foods' current size and growth trajectory. Juan reveals that the company currently employs 55 people, with most focused on operations and production at their Factory 01 facility. As they've achieved regulatory approval in the US market, they're now scaling up their commercial team to support ingredient sales and customer development.

The production capacity discussion reveals both current limitations and ambitious expansion plans. Current capacity at Factory 01 is relatively small compared to global protein demand, but Solar Foods has detailed plans for significant scaling. Their Factory 02 pre-engineering is underway, with startup planned for 2028.

Capacity expansion plans are substantial: Solar Foods aims to reach 12,000 metric tons annually by 2030, with modular expansion allowing them to scale production in phases. The first year targets 3,000 tons, expanding to 6,000 tons, and ultimately reaching the 12,000-ton target.

The conversation also touches on Solein®'s naturally high iron content, which offers particular benefits for female endurance athletes who commonly face iron deficiency challenges. Sini explains how this nutritional advantage, combined with Solein®'s complete amino acid profile, makes it especially valuable for women in sports and active lifestyles. The bioavailable iron in Solein® comes naturally from the microorganisms' biological processes, not from fortification or synthetic additions. This natural occurrence means the iron integrates seamlessly with the protein matrix, potentially offering better absorption and utilization compared to artificially fortified products.

-

1:00:00 - Global Flavors and Ice Cream Success

Ben asks about flavor developments beyond the American market concepts, and Sini reveals additional applications that have performed exceptionally well. Salty caramel has proven popular across multiple markets, along with pumpkin spice variations and various "brown flavors" that complement Solein®'s natural color properties.

Ice cream applications continue to be among Sini's favorite uses for Solein®, whether traditional ice cream or protein-enhanced frozen desserts. The protein provides excellent texture and mouthfeel while delivering complete nutrition, and the natural creamy characteristics work beautifully with a wide range of flavor profiles.

Berry applications developed by their product development chef showcase Solein®'s versatility with fresh, natural ingredients. These formulations work equally well in smoothies and frozen dessert applications, demonstrating the ingredient's adaptability across different product categories and serving temperatures.

The international success of various flavor profiles indicates broad consumer acceptance across different cultural taste preferences. This global appeal supports Solar Foods' strategy of expanding into multiple markets rather than focusing exclusively on specific regional preferences.

-

1:04:00 - Market Timeline and Consumer Availability

Ben asks the crucial question about when consumers can expect to find Solein®-based products in stores. Juan explains that Solar Foods has publicly announced partnerships with US companies that are currently in product development stages, with expectations for market launches in 2025.

Sensapure Flavors turned bright orange air-based protein into delicious salted caramel and chai beverages. When novel proteins change the game, Sensapure makes them taste good.

The timeline challenges reflect the realities of new product development, where Solar Foods provides ingredient support but ultimate launch timing depends on their customers' development and commercialization processes. While Solar Foods aims for products to reach shelves before year-end 2025, they acknowledge that new product development timelines can be unpredictable.

Customer partnerships involve supporting brands through the entire development process, from initial formulation through scaling and commercialization. Solar Foods provides technical support, application guidance, and regulatory assistance to ensure successful product launches.

The market entry strategy focuses on working with established brands rather than launching Solar Foods-branded consumer products. This approach leverages existing distribution networks and consumer relationships while allowing Solar Foods to focus on ingredient production and technical support.

-

1:07:00 - Contact Information and Industry Connections

As the conversation concludes, the team discusses how interested parties can connect with Solar Foods. Direct contact is welcomed through their website, where contact forms enable initial inquiries. Both Juan and Sini are accessible through LinkedIn for more personal connections and ongoing discussions.

Sensapure's role in supporting customer connections provides additional pathways for brands interested in Solein® applications. The partnership offers joint customer approaches, combining Solar Foods' ingredient expertise with Sensapure's formulation capabilities to deliver complete solutions.

Trade show presence continues to be important for Solar Foods, with plans for continued collaboration with Sensapure at industry events. These venues provide opportunities for hands-on product experiences and technical discussions that accelerate commercial adoption.

The "velvet lemon" flavor developed in partnership with Sensapure represents just the beginning of collaborative flavor innovation. Both companies remain committed to developing additional concepts that showcase Solein®'s versatility while meeting specific customer needs and market demands.

Where to Follow Solar Foods and Connect with the Team

- Juan Benítez-García: LinkedIn

- Sini Möttönen: LinkedIn

- Solar Foods:

- Company Website

- Learn more about Solein® on PricePlow

- Sign up for PricePlow's Solar Foods news alerts

Thank you to Juan and Sini for sharing the incredible story of Solein® and demonstrating how ancient Finnish microbes, renewable electricity, and innovative engineering are revolutionizing protein production. From 80% protein content with complete amino acids to NASA recognition for space applications, Solar Foods is pioneering a fundamental shift toward sustainable, location-independent nutrition that could reshape how humanity thinks about food production.

The future of protein isn't just plant-based or precision fermentation - it's literally made from thin air, and it's available right now. Subscribe to the PricePlow Podcast to stay updated on breakthrough ingredients and the innovators bringing them to market!

Comments and Discussion (Powered by the PricePlow Forum)