Solar Foods' Factory 01 in Finland produces Solein® protein from air molecules using chemosynthesis microbes. 20x more efficient than photosynthesis, no farms needed. Commercial protein production from literal air is now reality.

For the first time in human history, we're producing commercial quantities of protein without farms, without animals, and without even plants. Solar Foods has moved beyond theory and pilot programs -- their Factory 01 in Finland is actively utilising air molecules to grow nutritious protein powder through a technological platform that sounds like science fiction but operates like clockwork.

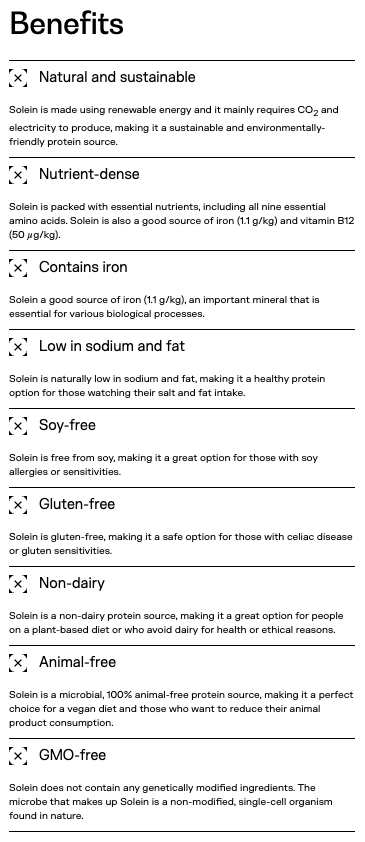

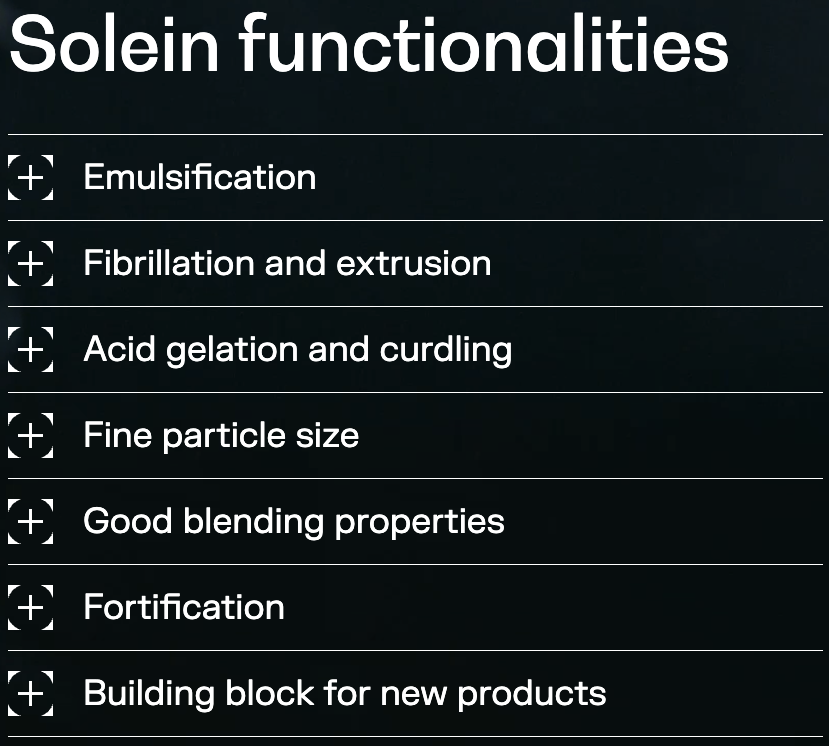

This protein comes in the form of Solein®, a revolutionary golden-yellow protein powder that's 80% protein with all essential amino acids, produced by naturally-occurring microbes that literally eat air. We recently sat down with Solar Foods' team in our podcast episode #175 to discuss how this ingredient is already appearing in products from ice cream to protein bars.

While our previous coverage of Solein® (linked above) explored the finished ingredient and its impressive nutritional profile, today we're pulling back the curtain on how this remarkable feat is achieved.

The technology involves two equally fascinating components: a gas fermentation platform that feeds microbes with literal air, and an ancient Nordic microorganism that performs chemosynthesis. It's a biological process that's 20 times more efficient than the photosynthesis powering all current food production. Sign up for PricePlow's Solar Foods news alerts to stay updated, and then let's get into the technical details:

Subscribe to PricePlow's Newsletter and Alerts on These Topics

The Dual Technology Platform: Hardware Meets Ancient Biology

Solar Foods' breakthrough isn't just one innovation, it's the marriage of cutting-edge bioprocess engineering with microorganisms that have been perfecting their craft for millions of years. Understanding both components reveals why this technology can succeed where others have only theorized:

Gas Fermentation: The Industrial Revolution of Protein

The hardware side of Solein® production centers on gas fermentation -- a process that feeds microbes with gases instead of agricultural sugars. The Solar Foods team describes it perfectly: "It's like a soda stream because we inject basically the gases in so that the microbe can eat."

The process begins with water electrolysis, where renewable electricity splits H₂O into hydrogen and oxygen gases.[1] This isn't just in textbooks: Factory 01's on-site electrolyzer operates continuously, producing the hydrogen that serves as the primary energy source for the microbes.

The Gas Diet That Feeds Protein Production

Inside 20,000-liter bioreactors, the microbes consume a precisely balanced gas mixture:

- Carbon dioxide (captured directly from air or industrial sources)

- Hydrogen (from water electrolysis)

- Oxygen (also from electrolysis)

The typical gas ratio maintains CO₂:O₂:H₂ at 1:2:7 volumetric proportions, creating optimal conditions for microbial protein synthesis.[1] The microbes also receive essential minerals including nitrogen, phosphorus, sulfur, iron, and other trace elements -- the same nutrients plants absorb through their roots, but instead delivered with pharmaceutical precision.

Chemosynthesis: Nature’s Alternative to Photosynthesis

While the fermentation hardware impresses, the real magic happens at the cellular level through chemosynthesis, which is a biological pathway that predates photosynthesis and operates with stunning efficiency. Instead of using sunlight like plants do, these microbes generate energy by breaking chemical bonds in hydrogen gas, then use that energy to convert CO₂ into proteins and other organic compounds.

Finnish company Solar Foods just made protein powder from literal air! Solein® uses microbes that eat hydrogen + CO2 to produce 78% protein with all essential amino acids. It's also already GRAS self-affirmed and in production.

The Finnish Microbe Discovery

The star of this show is a naturally occurring hydrogen-oxidizing bacterium discovered in Finland's pristine environment. These non-GMO microbes from the Xanthobacter genus have evolved over millions of years to thrive by oxidizing hydrogen gas for energy.[2]

As Susanna Mäkinen, Head of Biology at Solar Foods, explains: "The microbe at the heart of Solein®'s story was plucked from the rich biodiversity of Finland's nature. Little did it know that it would be the ancestor of trillions of similar yellow cells."

How Chemosynthesis Outperforms Photosynthesis

Unlike plants that need sunlight, Solein®'s chemosynthesis-performing microbes oxidize hydrogen molecules to release energy that powers CO₂ fixation into organic compounds.[3] This process achieves CO₂ reduction efficiencies that exceed natural photosynthesis, operating 24/7 regardless of weather or season.

The efficiency advantage is staggering: these microbes demonstrate many times higher efficiency than natural photosynthesis and approximately 200 times more efficiency than meat production.[4] This is the future of food efficiency, and it's already here in operation.

Factory 01: Where Theory Becomes Commercial Reality

Located in Vantaa, Finland (just north of Helsinki), Factory 01 isn't a pilot plant. It's a fully operational commercial production facility that launched in April 2024, proving that air-to-protein technology works at industrial scale.

Production Capacity That Delivers

The facility's specifications demonstrate serious commercial intent:

- Daily production: 450kg of Solein® powder

- Annual capacity: 160 tons

- Bioreactor volume: 20,000 liters for the main production vessel

- Production cycle: Continuous 70-hour fermentation cycles

- Operational schedule: 365 days per year

This continuous production model means "every day is a harvest day", as Solar Foods describes it. This is in stark contrast to seasonal agricultural cycles that dominate traditional protein production.

Renewable Energy: The Power Behind the Process

Factory 01's commitment to sustainability extends beyond the production method itself. The facility integrates multiple renewable technologies:

-

On-Site Electrolysis

The facility houses alkaline electrolysis units that achieve industry-leading system efficiencies. These units produce hydrogen and oxygen directly, eliminating the need for gas transportation and storage while maintaining precise control over gas purity and availability.

-

Direct Air Capture Integration

Incredibly, Factory 01 incorporates Direct Air Capture (DAC) technology to source CO₂ directly from the atmosphere.[1] Using amine-based sorbents that capture and concentrate atmospheric CO₂, this system can achieve purity levels exceeding 99.99% while operating on renewable energy.

The DAC system requires approximately 1.8-2.5 kWh of electricity and 0.35-0.45 kWh of thermal energy per kilogram of captured CO₂.[1] When powered by renewable sources, this creates a carbon-neutral -- or even carbon-negative -- protein production cycle.

It's worth noting that Factory 01 currently uses a hybrid approach for CO₂ sourcing -- combining DAC technology with liquid CO₂ to test both systems. As Solar Foods scales to future factories, they'll have flexibility in CO₂ sourcing, potentially utilizing industrial side streams as long as they meet green, clean, and food-grade standards. This adaptability ensures the technology can leverage the most sustainable and cost-effective CO₂ sources available at any given location.

Automation and Monitoring

The entire process operates under sophisticated automation, controllable from a central monitoring room or even remotely. Temperature, pH, gas concentrations, and nutrient levels are continuously monitored and adjusted, ensuring consistent product quality that agricultural systems can't match.

Efficiency Metrics That Redefine What’s Possible

The numbers behind Solein® production challenge everything we thought we knew about protein manufacturing efficiency.

Speed of Production

Traditional protein sources measure production cycles in months or years:

- Spring wheat: 100-130 days to harvest

- Winter wheat: 180-250 days

- Egg-laying hens: 5 months before production begins

- Solein®: 70 hours (~3 days) from start to harvest

This rapid turnaround enables Factory 01's bioreactor to produce the same daily protein output as 300 dairy cows or 50,000 egg-laying chickens... without the land, water, or environmental impact.

Resource Utilization

The efficiency extends to every input:

- Energy requirement: 18-30 kWh per kilogram of final biomass[1]

- Hydrogen conversion efficiency: Over 90%[1]

- Water usage: Primarily recycled within the system

- Land requirement: Factory footprint only -- no agricultural acreage

Biomass vs. Precision Fermentation Efficiency

It's crucial to understand that Solein® uses biomass fermentation, where the microbes themselves become the product after pasteurization and drying. This eliminates the complex genetic manipulation and processing required by precision fermentation, where engineered organisms produce specific proteins that must be separated and purified. The entire microbial biomass is harvested, making it a more efficient and waste-free process -- and it's a non-GMO process.

Scalability Without Geographic Limits

The technology's independence from traditional agricultural constraints opens possibilities that seemed impossible just years ago.

The New World Food Map

Solar Foods envisions a complete reimagining of global food production geography. Traditional breadbasket regions like the American Midwest or Southeast Asian rice paddies arose from agricultural necessities -- fertile soil, adequate rainfall, and moderate climates. But Solein® production flips this paradigm entirely.

Consider Chile's Atacama Desert, one of the driest places on Earth where Solar Foods' VP Arttu Luukanen recently visited. While inhospitable to traditional agriculture, the Atacama represents a future protein hub thanks to Chile's renewable energy potential from solar, wind, and geothermal sources. The country's ambitious carbon neutrality goals and educated workforce make it ideal for next-generation food production... not despite being a desert, but because it offers vast spaces for renewable energy generation without competing with existing farmland.

Chile's Atacama Desert showcases the barren landscape where Solar Foods could build future protein factories, powered by abundant solar energy instead of relying on fertile soil or rainfall.

This shift means today's agricultural impossibilities are tomorrow's protein capitals. The Sahara could become a major food producer through solar power. Greenland's glacial regions could harness wind energy for protein production. Energy availability, not soil quality, becomes the determining factor for where food gets produced.

Location Independence in Action

Because Solein® production requires only electricity, water, and air, facilities can be built anywhere:

The frozen landscape of Greenland demonstrates how Solar Foods' technology can operate in extreme cold environments, using renewable wind energy for protein production regardless of harsh weather conditions.

-

Desert Deployment

Abundant solar energy in arid regions becomes an asset rather than a challenge. No irrigation, no soil depletion, no concerns about drought -- just consistent protein production powered by the sun.

-

Arctic Operations

Factory 01 already proves the concept works in Finland's harsh winters, using renewable wind electricity to power the plant. The controlled indoor environment means -40°C outside temperatures don't affect production, bringing protein security to remote northern communities.

-

Urban Integration

Future facilities could operate in industrial areas near population centers, eliminating transportation emissions and bringing protein production directly to consumers. A warehouse in Brooklyn could produce as much protein as thousands of acres of farmland. Solar Foods could even plug into a city's district heat system or utilize CO2 sidestreams from other manufacturing plants, reducing emissions.

The Ultimate Proving Ground: Outer Space

Solar Foods' selection as an international winner in NASA's Deep Space Food Challenge validates the technology's potential for the most extreme environments imaginable. Competing against over 300 initial teams, Solar Foods demonstrated not just theoretical capability but practical solutions to humanity's greatest exploration challenges.

The International Space Station represents the ultimate testing ground for Solar Foods' technology, where their compact bioreactor system could feed astronauts while recovering precious water resources.

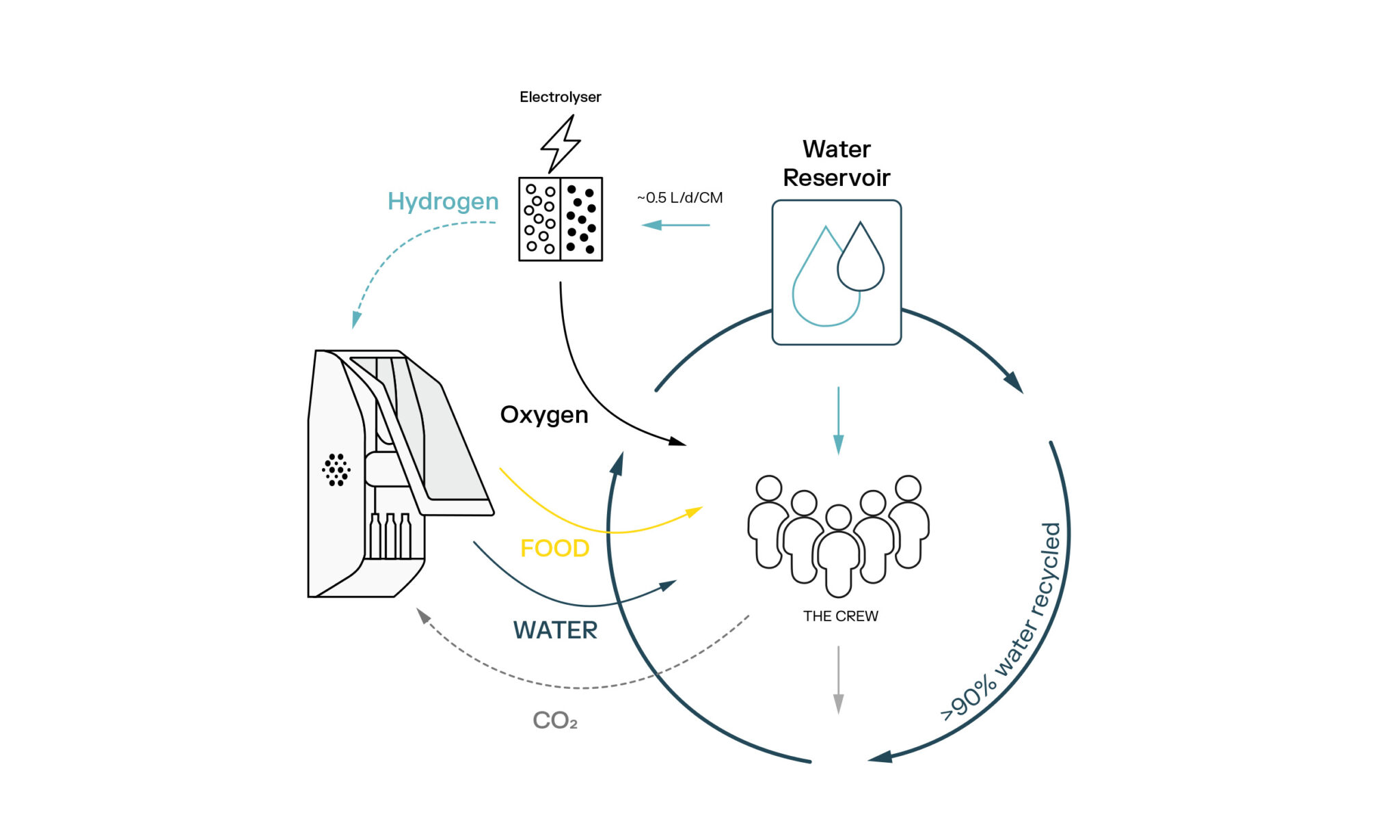

The breakthrough came when Solar Foods' team, led by Senior VP Arttu Luukanen, realized their technology could solve one of space exploration's most critical problems: the water loop. "In space habitats, oxygen is generated by splitting water molecules. While the oxygen is used by the crew, the hydrogen is typically vented into space, wasting valuable water", Luukanen explains. "By feeding this hydrogen and the CO₂ exhaled by astronauts into our process, we can recover the water while producing Solein® at the same time."

This diagram illustrates how Solar Foods' technology creates a closed-loop system in space habitats, converting astronaut-exhaled CO₂ and electrolysis hydrogen into protein while recovering over 90% of precious water.

This innovation aligns perfectly with NASA's recently published Decadal Survey advocating for bioregenerative life support systems. The space application demonstrates remarkable efficiency:

- A 40-liter bioreactor provides daily protein for six astronauts

- The system produces oxygen as a beneficial byproduct

- Water used in the bioprocess doubles as radiation shielding

- The process recovers water that would otherwise be lost to space

- Total system weight allows for viable Mars mission deployment

The distinctive golden color comes from Solar Foods' Xanthobacter microbes -- the same non-GMO organisms that convert hydrogen and CO2 into nutritious protein. Lab technicians regularly sample the protein powder to ensure consistent quality and that characteristic creamy texture with subtle umami notes.

The challenges of space production -- handling explosive hydrogen-oxygen mixtures, designing for microgravity, and ensuring complete automation -- have pushed Solar Foods to develop solutions that enhance terrestrial applications too. If it works in the vacuum of space with every gram scrutinized and every watt measured, it can work anywhere on Earth.

Currently, Solar Foods is working on scaling down their technology platform for smaller units that could support acute situations like defense applications or crisis response, bringing the lessons of space exploration back to Earth.

The Technology That Changes Everything

Solar Foods hasn't just created another alternative protein, they've developed a technological platform that fundamentally reimagines how humanity produces food. By combining gas fermentation hardware with naturally occurring microbes that perform chemosynthesis, they've achieved what decades of research only theorized: efficient, scalable protein production completely disconnected from agriculture.

Factory 01 stands as proof that this isn't laboratory speculation or venture capital hype. It's 160 tons per year of real protein, produced every single day regardless of weather, season, or climate. The technology operates at efficiencies that make photosynthesis look primitive, requires no arable land, and can be deployed anywhere from the Sahara Desert to the surface of Mars.

Juan Benítez-García and Sini Möttönen from Solar Foods reveal how ancient Finnish microbes and renewable electricity create Solein®, the revolutionary protein made "out of thin air" on Episode #175 of the PricePlow Podcast.

Science fiction we only could have dreamt of decades ago is now reality, in production right now. Solar Foods has given us a glimpse of the future, and it's powered by air, electricity, and some very clever Finnish engineering.

The implications extend beyond just feeding humanity. As Luukanen notes, "Think of the planet as Spaceship Earth. Just like in space, we need to close resource loops on our planet, making sure nothing goes to waste." By learning to manage the small circular loops of a spacecraft's life support system, we're developing the expertise to better manage Earth's larger ecosystems. This technology doesn't just offer a new way to produce protein, it offers a blueprint for circular economy principles that could reshape industrial processes across sectors.

You can also listen to the complete story with Juan Benítez-García & Sini Möttönen in Episode #175 of the PricePlow Podcast. Next month, we'll explore the nutritional profile of the finished Solein® protein and how it compares to traditional sources. But for now, take a moment to appreciate the elegance of this solution: A company that's not just trying to make agriculture more efficient. They're bypassing it entirely.

Solar Foods – Deals and Price Drop Alerts

Get Price Alerts

No spam, no scams.

Disclosure: PricePlow relies on pricing from stores with which we have a business relationship. We work hard to keep pricing current, but you may find a better offer.

Posts are sponsored in part by the retailers and/or brands listed on this page.

Comments and Discussion (Powered by the PricePlow Forum)