Purchasing supplements may seem like a relatively simple procedure - after searching online or at a local store, you pick out and buy the products you want. As straightforward as that sounds, the process to properly create those products in a legal and safe manner is far more complicated. Manufacturing effective, high-quality, uncompromised supplements is a challenging game, but those that play it right are rewarded tenfold.

Led by Mark Glazier and his fearless team, NutraBio has pushed the supplement industry to a new level! With a new facility, they plan on pushing it even further!

In August of 2019, PricePlow had the opportunity to take an exclusive behind-the-scenes tour of the manufacturing operations of NutraBio, the industry’s leading brand in terms of openness, lab-testing, and quality control. Finding anyone who holds their company and their products up to as high of a standard as NutraBio CEO Mark Glazier is a difficult task -- Mark and Team NutraBio have taken things above and beyond what’s commonplace within the industry when it comes to manufacturing products.

Mike’s exclusive NutraBio Plant Tour walkthrough!

It turns out there are tons of laws that supplement brands and manufacturers must follow (those laws are discussed further down in this article). If you want to see a company doing it right, we highly recommend watching our walkthrough with Mark, which provides a view of a part of the industry many don’t get the chance to see: a behind-the-scenes supplement manufacturing plant tour!

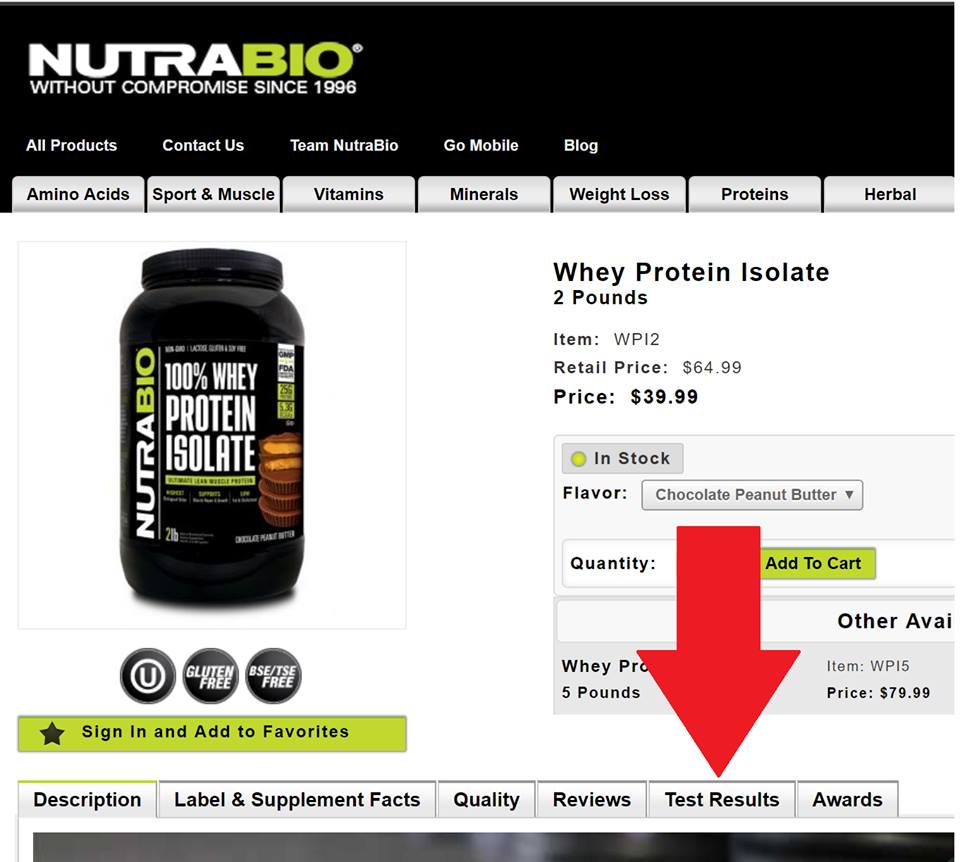

In this post, we’re going to outline PricePlow’s tour throughout the facility, highlighting the key areas within NutraBio’s operations. Before we get into that, make sure you’re subscribed to PricePlow. Not only will we get you more reviews, interviews, and unique insight like this, but we can help you find great deals on supplements, such as high-quality products from NutraBio!

NutraBio – Deals and Price Drop Alerts

Get Price Alerts

No spam, no scams.

Disclosure: PricePlow relies on pricing from stores with which we have a business relationship. We work hard to keep pricing current, but you may find a better offer.

Posts are sponsored in part by the retailers and/or brands listed on this page.

NutraBio - Implementing “BGMP” - Beyond GMP!

NutraBio has long held themselves to a higher standard than most. Since bursting onto the scene in 1996, CEO Mark Glazier has kept his company at the forefront of the industry, making top-level supplements without compromise, as you can read about in our original NutraBio Story.

NutraBio is known for their well-dosed, third-party-tested, validated, effective supplements, which are among the best in the industry. They’ve been extremely busy in 2019 with introducing new products and revitalized flavor systems. That's what the public has seen. But they’ve actually been even more active behind-the-scenes!

There are normal standards, and there are NutraBio’s standards

Although the supplement industry has a bit more freedom than most other consumer industries as far as regulations go, there are still required standards. Back in 2016, Mike and Mark actually discussed these laws, which every supplement company must follow:

Thanks to DSHEA 1994, the prevailing law of the land, the supplement industry finally had regulations instilled. On top of that, 21 CFR Part 111 implemented pharmaceutical-level regulations on the industry. That being said, due to wavering involvement of the FDA, some flexibility remained for companies, which inherently created variability of how good an individual brands practices actually are.

August of 2019 marked the grand re-opening of NutraBio’s manufacturing facility in Middlesex, New Jersey. After years of following and maintaining cGMP (current Good Manufacturing Practices) in the production of their formulas, NutraBio wanted to take things a step further. While things were already performing at a very high level (as evidenced by many FDA audits with no infractions), Mark Glazier had a wish list of an even more streamlined facility. So he went to work with hundreds of thousands of dollars towards an even higher-grade factory.

How is this awesome Root Beer Float Whey Protein Isolate made, you ask? With BGMP and NutraBio S.O.P.!

With a completely revitalized facility, NutraBio is now implementing what they’ve dubbed “BGMP”, or Beyond Good Manufacturing Practices. They’ve lived up to the minimum standard, but now want to be even better, setting new standards for themselves. With this approach, they can enhance their overall production, which increases the efficacy of their products, which ultimately benefits consumers!

This endeavor wasn’t cheap - NutraBio spent upwards of $500,000 within the final eight weeks prior to opening alone in revamping their facilities. The overall cost isn’t too important, however, considering the impact that BGMP can have on their business! By establishing, implementing, and now perfecting their standard operating procedures (S.O.P.), NutraBio ensures that every operation within their facilities is consistent from batch to batch, yielding consistently excellent and efficacious products. Their facility along with their highly-trained workforce smoothly running under these S.O.P. are what ultimately allows them to achieve these "BGMP" levels, and in our tour, we were able to get a firsthand account of what this approach entails!

The NutraBio Facility

Let’s go through the new facility, step-by-step!

-

Entering the facility - make sure you’re clean! (0:00)

While not all of the areas within NutraBio require it, most of them demand that individuals must be completely sanitized before entering. That means full sterilization - this ensures that outside organisms and bacteria stay on the outside, and don’t interact whatsoever with the product. NutraBio even has a detailed, six-step hand-washing process that everyone needs to follow! Once cleaned and dressed up in lab coats, masks, and other protective equipment, we can go see what else is going on inside!

-

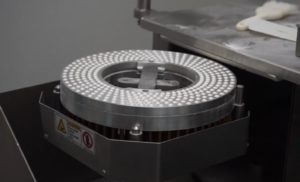

Testing Room (4:15)

Coming straight from the CEO himself, “the lab is the foundation of NutraBio”. This isn’t just where the supplement manufacturing process gets started, it’s also where we can begin seeing just how well-run the ship is at NutraBio. In the testing room lab, raw materials (which have been quarantined until they pass) are brought in and tested for compliance. After NB has identified qualified vendors, they bring in samples of their products to make sure they’re of adequate quality. Using Fourier Transform Near-Infrared (FTNIR) Spectrography, everything is tested quantitatively - and we mean everything!

FTNIR helps identify all the standards NutraBio has set - to make sure the raw material suppliers are providing what they say they're providing. Unfortunately, as Mark points out, this isn’t always the case -- NutraBio rejects between 8% to 11% of all incoming raw material, with their testing finding discrepancies in specifications. Ask yourself this - these companies know how strict Glazier and team are, and they still send failing products. What do you think they send to companies that aren't this strict??

If a given material passes all of these tests, however, NutraBio doesn’t stop there - they then send it out to a third-party lab for testing, further verifying an ingredient’s quality on a quantitative basis. Once these procedures are carried out, and they meet both sets of standards established by NutraBio and the original vendor, material is sent back and stored in isolation.

It’s worth noting that this vigorous testing is unconventional within the industry. Regulations only require an initial three-step testing process, after which a brand can use a vendor’s material without re-assessing. NutraBio doesn’t do that - no matter how long they’ve been working with a vendor, they test every single particle of ingredient that enters its doors.

That level of assurance should be the norm, and although it, unfortunately, is not, we appreciate the lengths NutraBio has gone to. Mark deems this the most challenging part of their operation, but challenge often brings the best out of people/organizations, and that seems to be the case here!

-

Quarantined Warehouse (11:12)

The quarantined warehouse contains all of NutraBio’s material that must be kept isolated from any possible contaminants until the aforementioned tests have been passed. This includes raw ingredients, bottle, scoop, and lid. Each item is palletized, shrink-wrapped, and stores with a seal of approval from a lab manager, verifying its contents. There’s an additional section for finished products, as well, which is stored following tests conducted after production.

The third-party-testing that NutraBio is famous for also gets mentioned here. Samples from finished batches are pulled from this warehouse and held onto for around one year past expiration to ensure a batch’s validity. On every NutraBio product, third party lab tests are public and you can find its lot number, which you can use to search for and find its lab results online.

-

Production Warehouse (13:52)

Back to the tour, once approved by quality control, material can be moved from quarantine into the production warehouse. Again, everything is labeled accordingly, fit with virtually every detail you can imagine - test results, quantity, contents, etc. From this area, employees can pull material needed for production and bring it to the production floor.

-

Pharmacy Room (36:20)

Those in the pharmacy room ensure that the right amount of every ingredient in products like Alpha EAA make it into the proper container!

Skipping ahead in the video, the next moment in the process is when the approved ingredients are ready to be weighed and brought into production. At this point, it is first sent to the ultra-clean pharmacy room. Here, two workers carry out a five-step process that ultimately separates material into the doses needed for a formula. The steps, conducted by two workers to ensure accuracy, are as follows:

- Validate labels, contents, weights, and other documentation.

- Material is weighed and separated based on production needs.

- Quality Assurance team checks everything - room environment, scales, material, etc.

- The amount that originally left the warehouse matches what is returning. For example, if the pharmacy room receives 20kg of leucine, the warehouse checks that its receiving 20kg (minus how much was used) back! No "disappearing" or unaccounted materials are ever allowed!

- A manager signs off on everything, verifying that each step in the procedure was followed and meant S.O.P. standards!

Material that leaves this room is then sent to production, which is where the real magic happens!

-

Blending (16:53)

NutraBio owns a ton of blenders, which work hard to make the blends, like NutraBio Pre, that we've come to know and love!

Now that ingredients have been thoroughly tested, weighed, and separated, they’re ready to be mixed into a formula! This process slightly differs based on the type of product being made, but the general rules and steps remain consistent. Initially, all material is again verified and weighed by two individuals. After blending, samples are taken from three different locations - the top-left corner, the middle-center wall, and the bottom-right corner - to validate that a homogenous mixture has been created. The type of blending, however, is where things get very interesting.

Mark discusses the involved science behind mixing more complex formulas, such as intra-workout products. NutraBio has various blenders with a range of sizes and capacities and depending on the product, the right blender is chosen and optimally filled. This is crucial, as this affects the physics behind the actual mixing. As the blender turns, material rides up the sidewall and crests over in a wave-like fashion. With material on the top and bottom moving in this way, the two “collide” in the middle, ultimately creating a blended mixture. If too much material is added, not enough collision occurs. Likewise, if too little material is added, too much movement keeps from yielding an appropriate mixture!

For products such as NutraBio Classic Whey, ribbon blenders are used. These machines aren’t as complex, as they simply blend ingredients from the bottom-up. They also allow for a bit more freedom in terms of loading, so NutraBio can add more material here without worrying about altering the mixing process. If pre-blends need to be added, such as the multivitamin powder that’s added to Muscle Matrix MRP, it’s done so after being blended in the fashion we’ve previously described!

Blending length, machine specifications (such as RPM), and process steps are crucial here. If NutraBio’s S.O.P. aren't followed, then creating a consistent product becomes very difficult! Via an extremely optimized process, they can create effective blends that go beyond what their competitors can make!

-

Encapsulating/Bottling (26:48)

Once the formula is properly created, they’re effectively encapsulated or bottled, depending on the product. NutraBio does something unique here - they’ve removed all excess chemicals from this process, including the use of chemicals commonly used to ease the manufacturing process. This leaves simply the capsule/bottle and the active ingredient, which is all you really want in your product!

NutraBio has the resources to really ramp things up in this process. They have machinery that can create a ridiculous 200,000 capsules per hour, as well as semi-automatic machines that, when manned by an operator, can make between 30,000 and 50,000 capsules per day. That’s good news - although NutraBio doesn’t usually use all of these machines often, products like UpSorb are in high demand, and production may need to speed up at times!

NutraBio takes the maintenance of these rooms/machines very seriously, as well. All excess fine powders are pushed out of these rooms by pressurized air and are filtered out of the facility completely. Additionally, everything is disassembled and cleaned between batches, with additional maintenance and cleaning conducted over weekends. These are more precautions taken that ensure an incredibly well-crafted product!

If final products are within plus-or-minus one percent of standard, they are deemed finished and good for sale. If so, containers are stored back in quarantined warehousing by batch. They’re not finished, however - they need some good ol’ NutraBio branding!

-

Labeling (36:02)

This one is pretty self-explanatory - finished containers are moved through a production line that throws the appropriate label onto containers. Headlined by the NutraBio name, this also stamps the product name and ingredients panel that we’re familiar with!

-

Shipping (14:50)

Before you get your hands on the Grape Berry Crush flavor system, the products are shipped out here!

Completely finished goods are stored in quarantine, but are moved to shipping once they’ve been ordered! NutraBio operates with over 300 SKUs, which makes the shipping process very challenging. In fact, they’re planning on moving their current six-station shipping operation into its own building in order to increase efficiencies here. The demand is growing, and NutraBio is growing with it!

Whether fulfilling an individual order from their online store or shipping to a distributor, this is the final step in NutraBio’s process. Thanks to their BGMP and S.O.P., NutraBio is confident that at this point, everything leaving their doors is top-notch, has their stamp of approval, and is something they are proud of!

Conclusion - NutraBio goes above and beyond for industry-leading quality!

Although the methodology is a bit complex, it works! NutraBio's BGMP and S.O.P.s are what gets you some of the best supplements available!

Clearly, manufacturing supplements is not an easy process. There’s an incredible amount of detail, care, and science that goes into it, making it extremely complex. And while there are industry regulations, there are still some freedoms that companies could exploit if they wanted to, which breeds variation in quality.

With their BGMP and S.O.P. in place, Mark Glazier and Team NutraBio have taken steps to rid their operations of as much variability as possible. With rigorous testing, highly-effective procedures, and top-notch equipment and staff, NutraBio is able to produce some of the best formulas on the market. And given how massively-dosed some of these sports nutrition formulas are, this isn't easy!

After seeing what they’ve got going on at their revitalized facility in New Jersey, we now know why! NutraBio puts their customers first, ensuring the quality and effectiveness of their products. Mark Glazier and his team at NutraBio run a tight ship behind-the-scenes, which allows them to best an industry leader that we truly appreciate!

Be on the lookout for things to come from NutraBio in the future - they didn’t just implement all of these practices for nothing! They have some big things coming soon, and you won’t want to miss it!

NutraBio – Deals and Price Drop Alerts

Get Price Alerts

No spam, no scams.

Disclosure: PricePlow relies on pricing from stores with which we have a business relationship. We work hard to keep pricing current, but you may find a better offer.

Posts are sponsored in part by the retailers and/or brands listed on this page.

Comments and Discussion (Powered by the PricePlow Forum)